Amorphous Cores Series

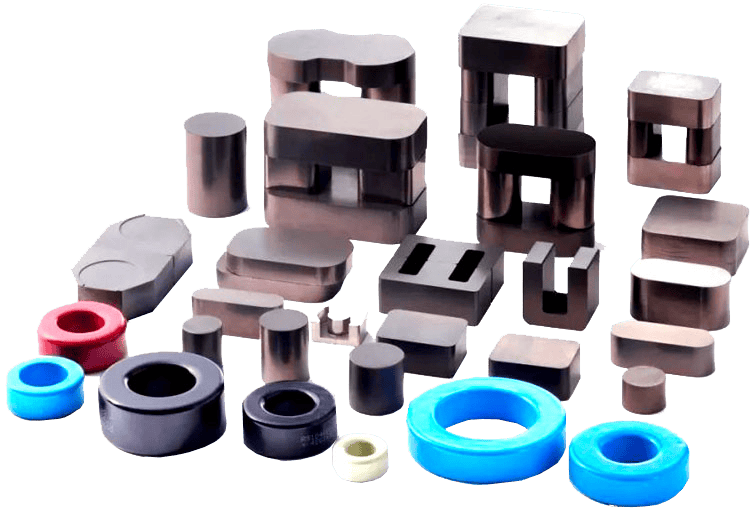

High Performance Amorphous Cores, manufactured by specialized amorphous core manufacturers such as Pourleroi, utilize a unique non-crystalline alloy material. These amorphous magnetic cores offer exceptional properties, including low core losses and high saturation flux density, making them ideal for a wide range of applications in power electronics. Their advanced design and construction make them highly efficient and suitable for demanding environments, enhancing energy efficiency and reducing power consumption.The amorphous core series, comprising amorphous blocks , amorphous E-cores , and amorphous C-core configurations , utilizes high-performance amorphous core material. These advanced cores, manufactured by specialized amorphous core manufacturers like Pourleroi, offer exceptional properties such as low core losses and high saturation flux density. They are designed to meet the demands of various applications in power electronics, providing flexibility and versatility in design and implementation.

-

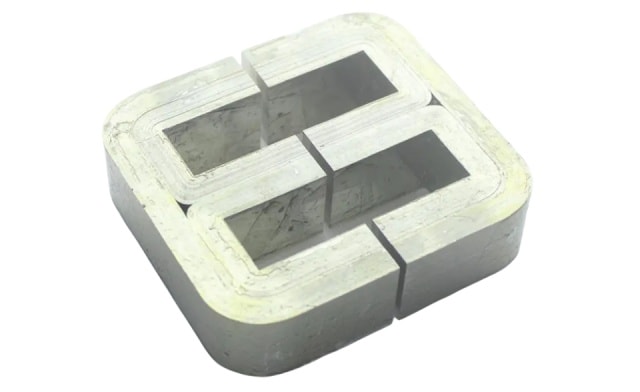

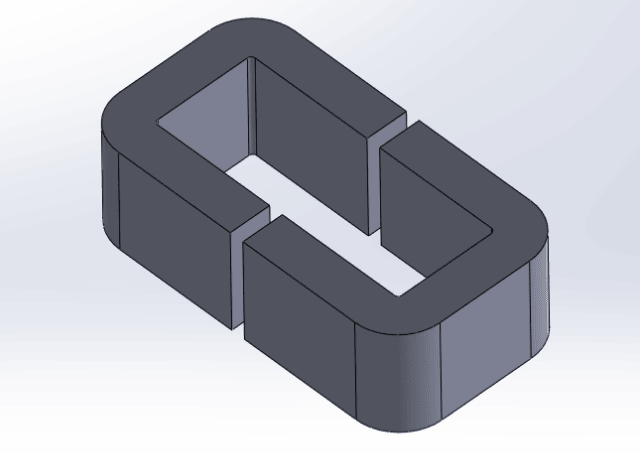

New Design HCT Amorphous Transformer Core

Low core loss,

Learn More >

Small permeability degradation -

Amorphous Big Triangle Core In Power Systems

Low core loss,

Learn More >

Small permeability degradation -

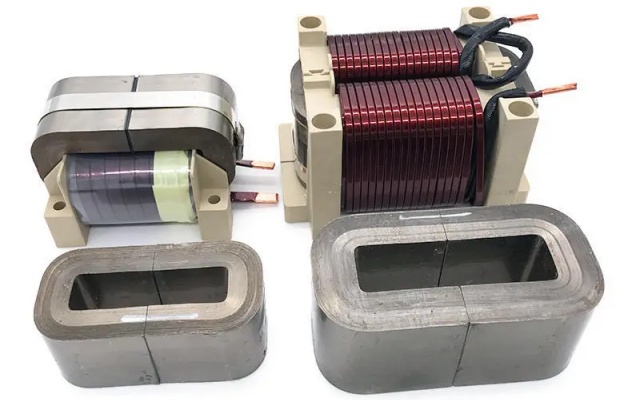

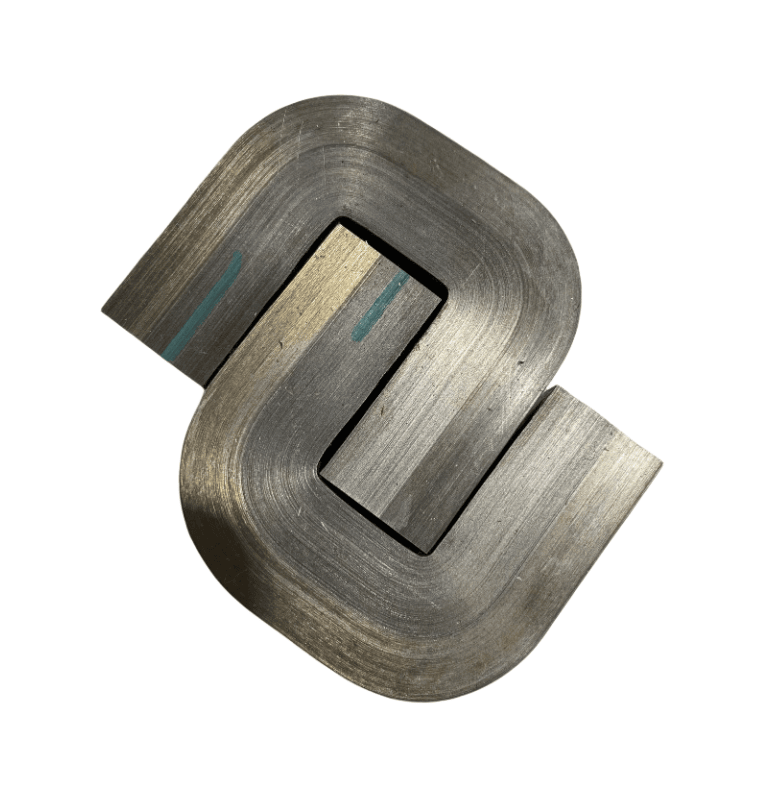

Amorphous Cutting Core C Core With Coating

Easy for coil assembling,

Learn More >

Low core loss -

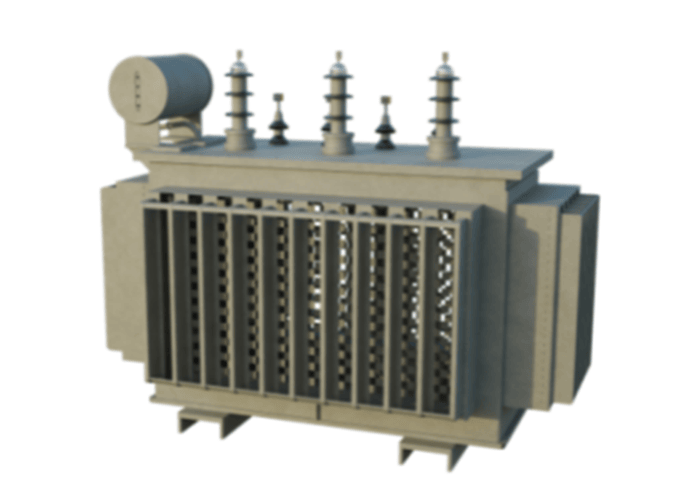

High Quality Amorphous Core Transformers

High permeability,

Learn More >

Low core loss -

Amorphous E Cores For High Frequency Electronics

Low core loss,

Learn More >

Small permeability degradation -

High Quality And Low Loss Amorphous Cut Core AMCC Core From Pourleroi

Small permeability degradation,

Learn More >

Low core loss -

Leading Quality ISO Qualification Toroidal Amorphous Gap Core PFC Choke

Easy for coil assembling,

Learn More >

Low core loss -

Amorphous Cut Core C Transformer Core For Audio Amplifier Transformer

Easy for coil assembling,

Learn More >

Low core loss -

Switching Power Supply Material Used From Customized Amorphous Distributed Transformer Cores

High permeability,

Learn More >

Low core loss -

Hot Sale Amorphous Block Core For Transformers

High permeability,

Learn More >

Low core loss

Industry Application

The versatility of amorphous cores makes them suitable for various fields such as transformers and inductors, sensors and detectors, power electronics, and high-frequency applications, achieving improved energy conversion efficiency, reduced energy loss, and providing stable signal processing and transmission capabilities.

FAQ

-

What are the performance parameters of amorphous cores?

1. Saturated magnetic induction intensity (Bsat): Saturated magnetic induction intensity refers to the maximum value at which the magnetic induction intensity of a magnetic core material reaches saturation under the action of an external magnetic field. A higher saturation magnetic induction intensity means that the magnetic core material can store more magnetic energy and has a higher magnetic saturation ability.

2. Coercivity (Hc): Coercivity refers to the external magnetic field strength required to reduce the magnetic induction intensity of a magnetic core material to zero under the action of demagnetization. A higher coercivity means that the magnetic core material has a higher anti-magnetization ability and can maintain stable magnetic properties under the action of an external magnetic field.

3. Hysteresis loss (Pv): Hysteresis loss refers to the energy loss generated by magnetic core materials during magnetization and demagnetization processes. Lower hysteresis loss means that the magnetic core material has lower energy loss and can provide higher energy conversion efficiency.

-

What is the application of amorphous cores?

1. Transformers and inductors: Amorphous cores are widely used in transformers and inductors. Its high saturation induction intensity and low hysteresis loss give it advantages in efficient energy conversion and electrical energy transmission. The low hysteresis loss of amorphous magnetic cores can reduce energy loss and improve system efficiency.

2. Power electronics applications: Amorphous cores are also widely used in the field of power electronics, such as switch-mode power supplies, frequency converters, motor drivers, etc. Amorphous cores can provide efficient electrical energy conversion, while also having lower temperature rise and thermal dissipation, which helps to improve the stability and efficiency of the system.

3. Sensors and detectors: Due to their high magnetic permeability and low hysteresis characteristics, amorphous cores are widely used in sensors and detectors. For example, used in magnetic sensors, current sensors, magnetic memory, and magnetic stripe read/write heads.