Why Choose POURLEROI as Your High Flux Core Supplier?

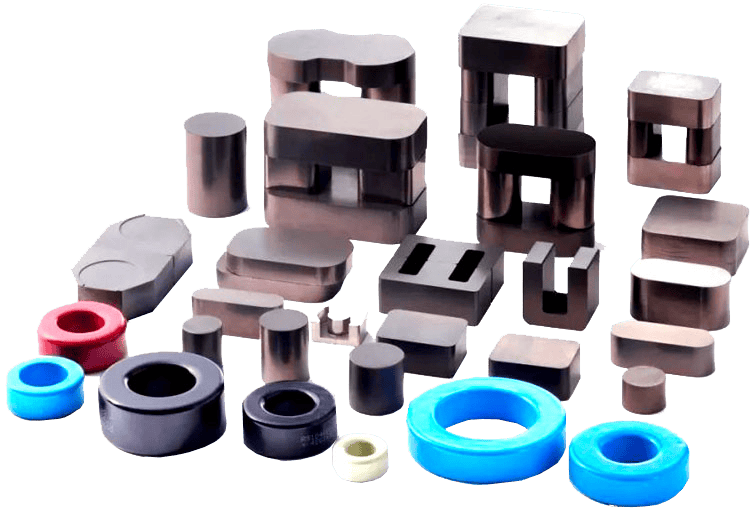

POURLEROI offers over 15 years of experience in advanced magnetic core manufacturing, with full customization services for high flux cores used in mission-critical power systems. We support tailored material selection, custom geometries, AL tuning, and various coating options to match specific engineering requirements.

All cores undergo rigorous testing for thermal stability, core loss, and inductance accuracy. We work directly with your engineering team to optimize magnetic design for PFC, SMPS, EV onboard chargers, and industrial power modules. With reliable lead times, global compliance (RoHS/REACH), and responsive technical support, POURLEROI is your trusted high flux core partner.

Applications of POURLEROI High Flux Cores

High flux cores from POURLEROI are widely used in high-current and high-frequency power electronics where compact size and thermal performance are critical. In power factor correction (PFC) circuits, their high saturation flux enables smaller inductors that handle strong ripple current without loss of efficiency. For switching power supplies and flyback transformers, high flux cores offer reduced core loss and excellent AC flux handling at high switching frequencies.

These cores are also applied in pulse transformers and series-mode EMI filters, where high energy transfer and magnetic stability are essential under dynamic loads. In electric vehicles and renewable energy systems, POURLEROI’s high flux cores help designers minimize size while maximizing performance in space-constrained power modules. Whether for telecom DC/DC converters or industrial motor drives, our high flux cores deliver robust magnetic performance in the most demanding environments.