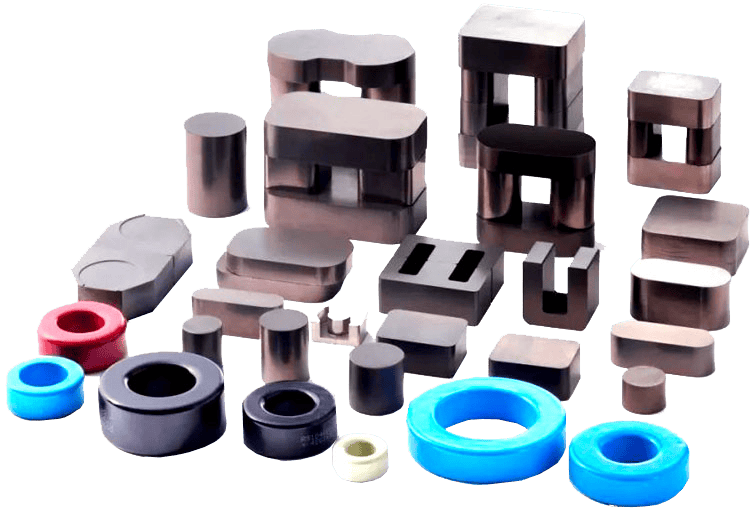

Nanocrystalline Cores Series

Nanocrystalline Cores for High-Frequency and High-Power Applications

POURLEROI’s nanocrystalline cores offer superior magnetic performance in compact sizes, with ultra-high permeability, low core loss, and high saturation flux density. Designed for high-frequency power electronics and EMI suppression, these cores are widely used in inverters, EV power modules, and high-efficiency inductors.

What Are Nanocrystalline Cores?

Nanocrystalline cores are soft magnetic components made from ultra-fine metal alloy ribbons (typically Fe-based) with nanometer-scale grain sizes. These materials are produced by rapid quenching and controlled annealing to achieve high permeability (μr up to 100,000+), low coercivity, and excellent temperature stability. Compared to ferrite, amorphous, or powdered cores, nanocrystalline magnetic cores provide superior performance in high-frequency, high-current, and compact circuit designs.Product Overview

POURLEROI’s nanocrystalline cores are available in a wide range of shapes, including toroidal, C-core, and rectangular formats. These cores exhibit high saturation flux densities (~1.2 Tesla) and extremely low core losses across frequencies from 10kHz to 500kHz. Thanks to their high permeability, they are ideal for current transformers (CTs), common mode chokes (CMCs), and high-frequency power converters.We offer both standard and custom AL values, optimized coating types (epoxy, polyester, insulation film), and optional cut gaps for DC bias tolerance or EMI suppression. Our cores are used in demanding applications such as EV onboard chargers (OBCs), PV inverters, smart grid filters, switching power supplies, and medical-grade transformers.

All POURLEROI nanocrystalline cores are produced under ISO9001-certified processes, with full RoHS and REACH compliance, ensuring high consistency and regulatory compatibility for global clients.

-

Solid State Transformer (SST)

Solid State Transformer (SST)

Learn More > -

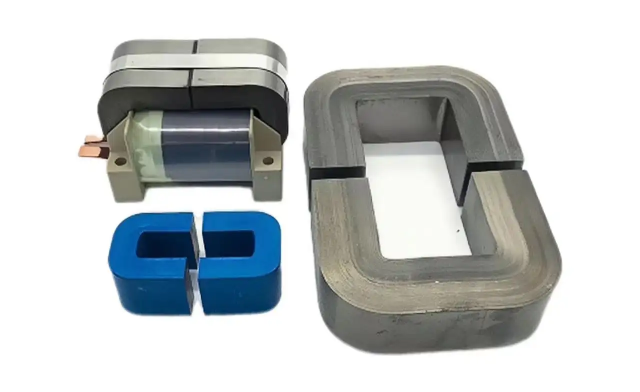

High Frequency Nanocrystalline Cut Cores Transformer Cores With Factory Price

High permeability,

Learn More >

Low core loss over wide frequency range -

Nanocrystalline Cores Soft Magnet Ring Core Current Transformer

Excellent frequency character,

Learn More >

Low magnetostriction -

High Performance Custom Chokes EMC Nanocrystalline Cores

Excellent frequency character,

Learn More >

Low magnetostriction -

High Quality High Performance Customized Nanocrystalline Rectangle Core

Excellent frequency character,

Learn More >

Low magnetostriction -

High Permeability High Frequency Transformer Core Nanocrystalline Cut Core

High permeability,

Learn More >

Low core loss over wide frequency range -

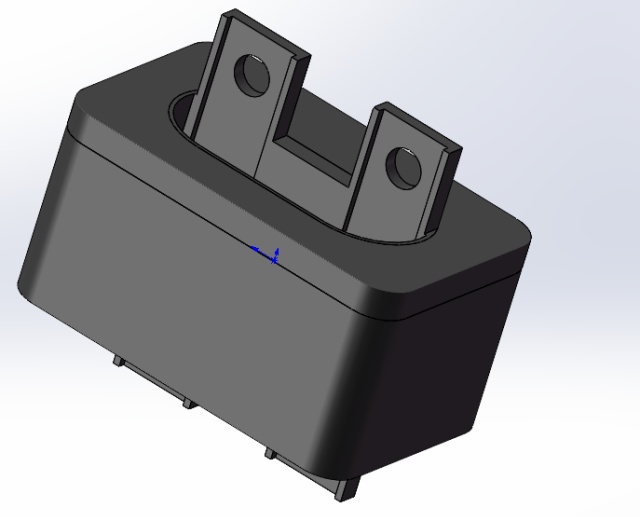

High-performance Material For Versatile Applications Of Nanocrystalline Ovale Core With Plastic Case

Excellent frequency character,

Learn More >

Low magnetostriction -

Low Core Loss Nanocrystalline Toroidal Core Circular Core With Cheap Price High Quality

Excellent frequency character,

Learn More >

Low magnetostriction -

Customized Nanocrystalline Ovale Cores For Common Mode Chokes

High saturation magnetic flux density,

Learn More >

Low core loss over wide frequency range -

Core Manufacturers High Power Nanocrystalline Core

High permeability,

Learn More >

Low core loss over wide frequency range -

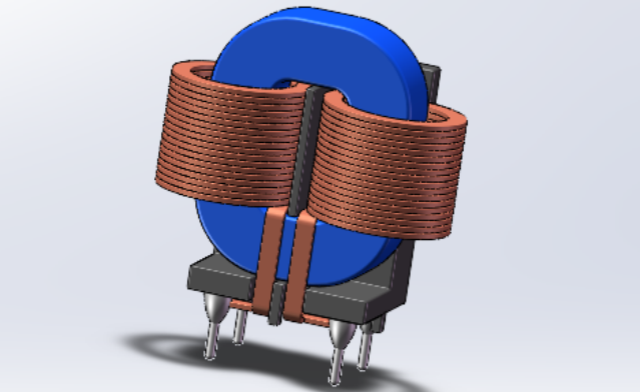

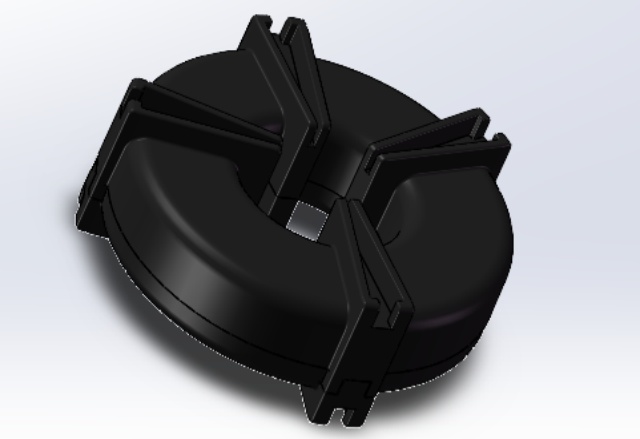

Common Mode Choke Made Of Nanocrystalline Cores

High permeability,

Learn More >

Low core loss over wide frequency range -

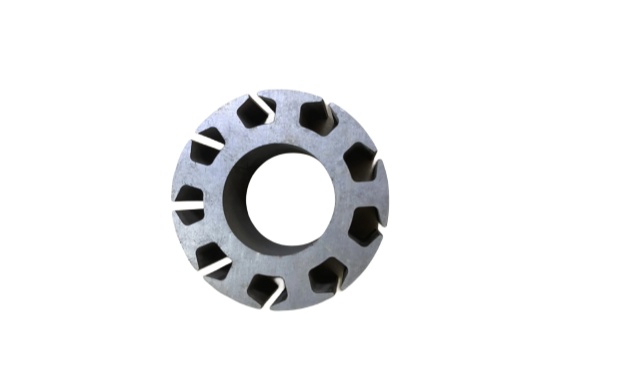

Nanocrystalline Stator Core For High-Speed Motor

High permeability,

Learn More >

Low core loss over wide frequency range

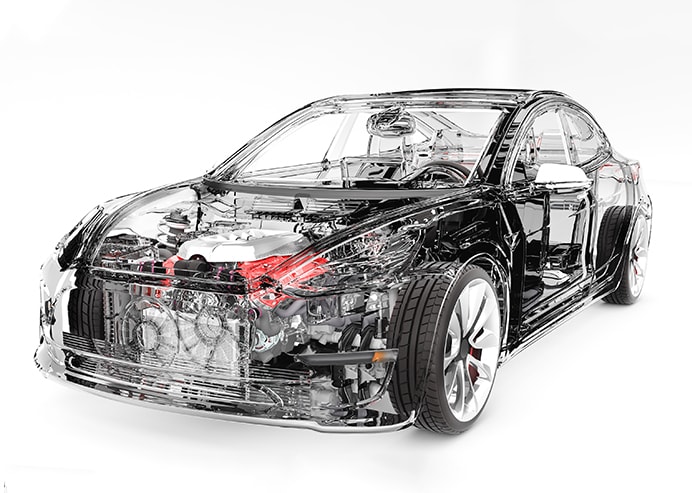

Industry Application

The versatility of nanocrystalline cores positions them as essential components in diverse fields, including automotive electronics, communication technology, medical equipment, and welding applications. Leading nanocrystalline core suppliers provide innovative solutions that achieve efficient power management, enhanced signal processing, and superior electromagnetic compatibility. With their unique magnetic properties, nanocrystalline core manufacturers produce high-quality products that significantly improve performance, efficiency, and reliability. Notably, nanocrystalline tape wound cores are particularly valued for their exceptional characteristics, enabling advanced applications that meet the demands of modern technology. By integrating these cores, industries can unlock new levels of operational excellence.

FAQ

-

What are the advantages of nanocrystalline cores?

1. High saturation magnetic induction intensity: Nanocrystalline cores have a high saturation magnetic induction intensity, which means they can store more magnetic energy. This enables nanocrystalline cores to have higher efficiency and smaller volumes in energy storage and conversion applications.

2. Low hysteresis loss: Nanocrystalline cores have low hysteresis loss, which means that the energy loss generated during magnetic field changes is relatively small. This means that in high-frequency applications, nanocrystalline cores can reduce energy loss and heat generation, and improve system efficiency and stability.

3. High-temperature stability: Nanocrystalline cores have good high-temperature stability and can maintain their magnetic performance in high-temperature environments. This gives nanocrystalline cores advantages in high-temperature applications, such as high-temperature power electronic devices and automotive electrification.

-

What are the differences between nanocrystalline cores and other soft magnetic materials?

1. Preparation process: The preparation of nanocrystalline cores usually adopts special processes, such as rapid solidification, sol-gel, and heat treatment. The preparation process of traditional soft magnetic materials is relatively simple. The preparation process of nanocrystalline cores requires higher technical requirements and cost investment.

2. Magnetic permeability( μ): Nanocrystalline cores typically have higher magnetic permeability, which means they can more effectively conduct and concentrate magnetic fields. In contrast, traditional soft magnetic materials have lower magnetic permeability. High magnetic permeability enables nanocrystalline cores to provide better performance in applications such as sensors and inductors.

3. Magnetic saturation induction intensity (Bs): Nanocrystalline cores typically have higher magnetic saturation induction intensity, which means they can store more magnetic energy. In contrast, traditional soft magnetic materials have lower magnetic saturation induction intensity. This gives nanocrystalline cores advantages in efficient energy conversion and energy storage applications.