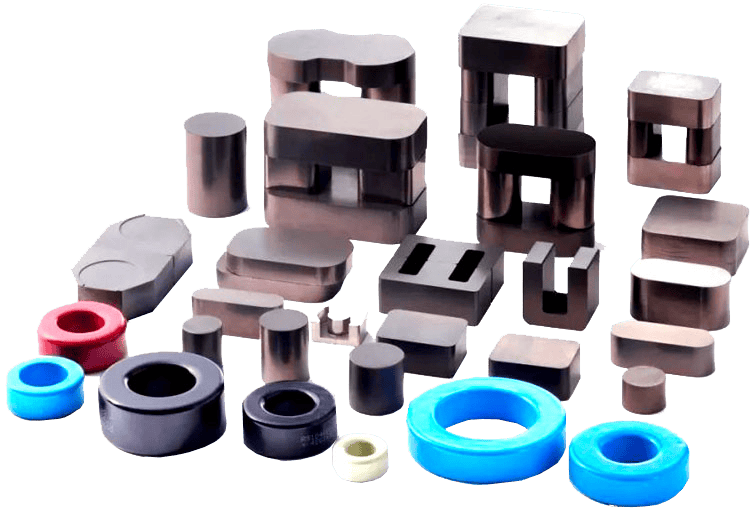

Why Choose POURLEROI as Your Combined Core Manufacturer?

As a factory-direct supplier with over 15 years of experience in soft magnetic materials, POURLEROI specializes in designing and manufacturing complex core combinations for mission-critical applications. We support full OEM/ODM customization, including hybrid material matching, precision shaping, AL tuning, and thermal protection coatings.

Our combined magnetic cores are produced with tight process control to ensure uniform magnetic properties, mechanical stability, and long-term reliability under high loads. We collaborate closely with engineering teams during the design and prototyping phase to shorten development cycles and ensure seamless integration into your power systems.

Choosing POURLEROI means partnering with a magnetic expert capable of delivering optimized, scalable hybrid core solutions for advanced industries.

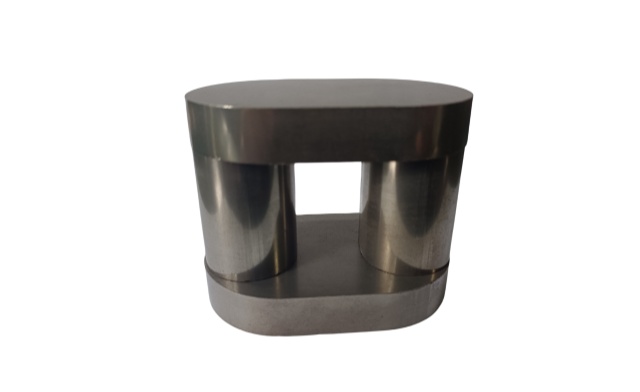

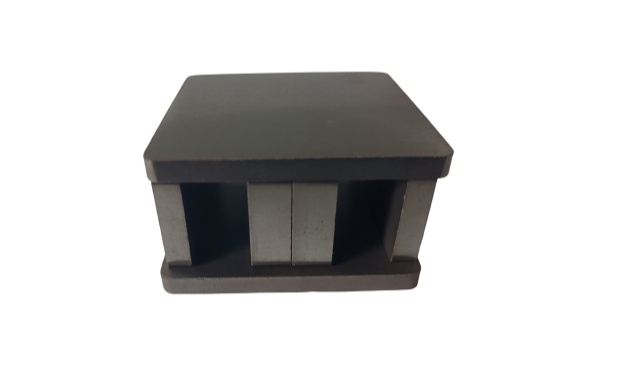

POURLEROI’s combined magnetic cores are tailored for system integrators and OEMs who face complex power design challenges in high-density, high-reliability environments. In renewable energy systems, they are used in solar inverters and energy storage converters where balancing efficiency and EMI compliance is critical. In EV and hybrid vehicle platforms, combined cores support onboard chargers (OBCs), battery management systems, and high-power DC/DC converters by delivering stable inductance and compact design. Telecom equipment manufacturers benefit from hybrid cores in switching regulators and isolation transformers where core loss and thermal stability must be tightly managed. For industrial automation, these cores serve in power supplies, servo systems, and motor controllers where multi-function magnetic integration reduces board space and improves thermal performance. Designed for engineers who demand custom-fit, high-efficiency magnetic assemblies, POURLEROI’s combined cores offer flexibility without compromising on performance or compliance.