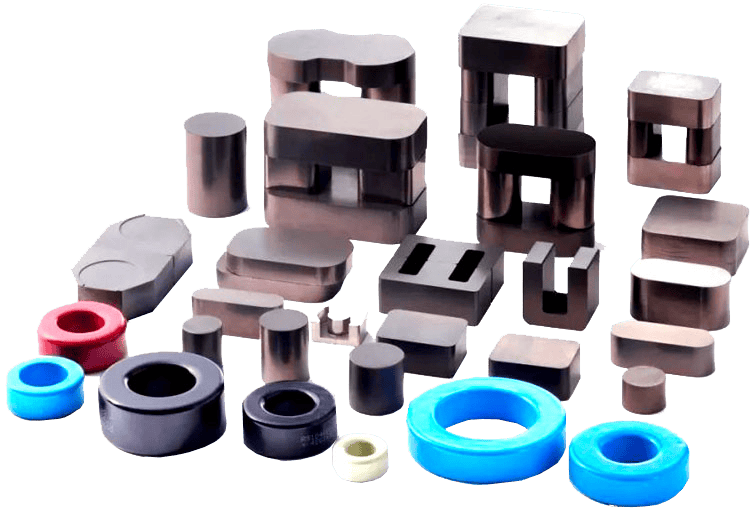

Why Choose POURLEROI for High DC Sendust Cores?

With over 15 years of powder core manufacturing experience, POURLEROI offers OEM/ODM services to global industrial clients seeking tailored magnetic solutions. We provide tight AL value tolerance control, fast prototyping, and scalable production capacity with full engineering support.

Our high DC bias Sendust cores are manufactured under ISO9001-certified systems and comply with RoHS/REACH standards. We assist clients in magnetic simulation, EMI testing, and thermal design, ensuring every core meets both functional and regulatory requirements for high-reliability systems.

POURLEROI’s Sendust cores are widely used in high-efficiency power electronics where large DC currents and ripple conditions are present. In power factor correction (PFC) stages, they allow engineers to reduce core size while maintaining inductance. In automotive DC-DC converters and onboard chargers, these cores withstand high bias without saturation, ensuring compact and efficient design.

They are also employed in output chokes for telecom rectifiers, inverter circuits in solar/wind energy systems, and EMI filters for industrial automation. Thanks to their distributed gap structure and low core loss, Sendust cores are a go-to solution for engineers seeking magnetic stability, compact size, and thermal robustness in high-current environments.