Products

-

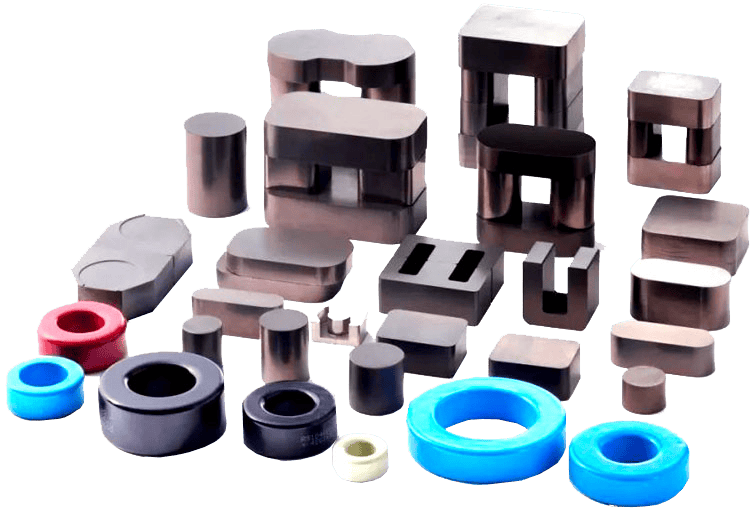

Customized High Quality Neodymium Magnetic Materials With Good Price

High permeability,

Learn More >

Low core loss over wide frequency range -

Super Strong Hot-selling Rectangular Magnet Neodymium Permanent Magnetic Materials

High permeability,

Learn More >

Low core loss over wide frequency range -

Best Price And High Quality OEM/ODM Transformer Core Silicon Steel Core

High magnetic conductivity,

Learn More >

Low hysteresis loss -

China Supplier Permanent Magnetic Magnet Block Strong Neodymium

High permeability,

Learn More >

Low core loss over wide frequency range -

43*36*10mm Different Size Factory Amorphous Block Core Low Price

High permeability,

Learn More >

Low core loss -

Nanocrystalline Cores Soft Magnet Ring Core Current Transformer

Excellent frequency character,

Learn More >

Low magnetostriction -

Customized Hot Sale Ndfeb Ring Magnet Circle Shape Neodymium Magnet With Factory

High permeability,

Learn More >

Low core loss over wide frequency range -

Soft Magnetic Silicon Steel Core For Transformer core

High magnetic conductivity,

Learn More >

Low hysteresis loss -

High Frequency Soft Magnetic Cores Sendust Cores For Transformer

High saturation,

Learn More >

low loss,stable performance -

High Performance Custom Chokes EMC Nanocrystalline Cores

Excellent frequency character,

Learn More >

Low magnetostriction -

High Temperature Strong Magnet SmCo Materials Manufacturer

High permeability,

Learn More >

Low core loss over wide frequency range -

Free Samples High Performance NdFeB Rectangular Magnet Neodymium

High permeability,

Learn More >

Low core loss over wide frequency range