- Feature

- Performance

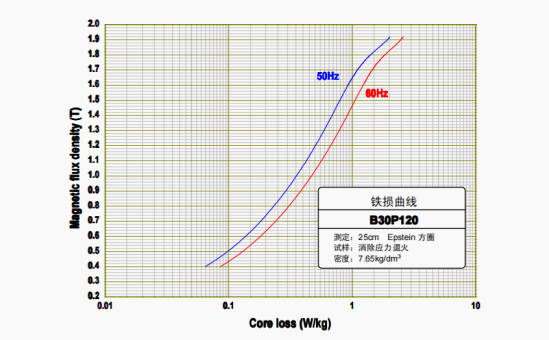

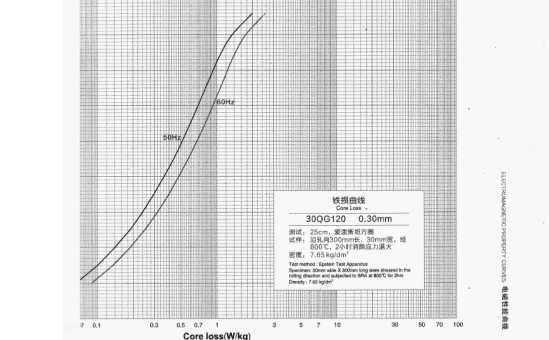

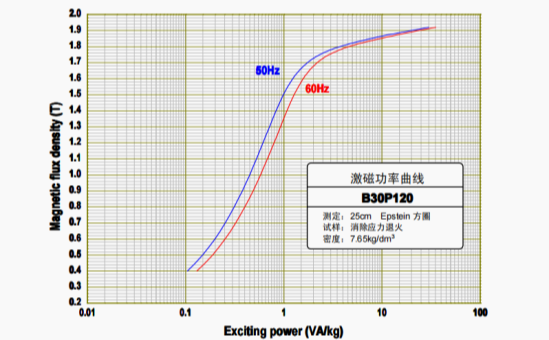

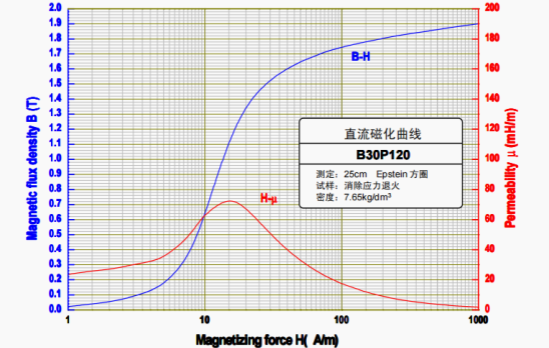

- Curve Comparison Chart

- Advantage

- Applications

- Video

Feature

Feature Description

Reduce hysteresis loss;

Increase magnetic flux density;

Provide corrosion and wear resistance performance;

Reduce noise and vibration.

Performance

High magnetic conductivity

Silicon steel transformer cores have high magnetic conductivity, which can effectively conduct and concentrate magnetic fields. This enables transformers to transmit and convert energy more efficiently, improving energy conversion efficiency.

Low hysteresis loss

The addition of silicon element to the core of silicon steel transformers can effectively reduce hysteresis loss. Hysteresis loss is the energy loss generated by magnetic materials when the magnetic field changes. Low hysteresis loss can reduce energy loss and improve the efficiency of transformers.

Low magnetic permeability

The core of a silicon steel transformer has a lower magnetic permeability, that is, a lower magnetic permeability. This is because in transformers, it is necessary to control the path and distribution of magnetic flux to reduce magnetic leakage. Low permeability silicon steel cores help to concentrate magnetic fields, reduce magnetic flux leakage, and improve energy transfer efficiency.

High saturation magnetic induction intensity

The silicon steel transformer core has a high saturation magnetic induction intensity. The saturation magnetic induction intensity refers to the maximum magnetic induction intensity that a material can withstand when saturated. The high saturation magnetic induction strength of silicon steel iron core enables transformers to withstand high magnetic flux density and improve energy transfer efficiency.

Low noise and vibration

The design and structure of the silicon steel transformer core help to reduce noise and vibration. By using reasonable core geometry and clamping methods, magnetic flux leakage and core vibration can be reduced, thereby reducing the noise level of transformers and improving their stability and reliability.

Curve Comparison Chart

Advantage

-

01

Reducing magnetic leakage

The design and structure of the silicon steel transformer core can help reduce magnetic leakage. By adopting a reasonable core geometry and clamping method, the magnetic field can be concentrated, the leakage of magnetic flux can be reduced, and the efficiency of energy transmission can be improved.

-

02

High magnetic conductivity

Silicon steel transformer cores have high magnetic conductivity, which can effectively conduct and concentrate magnetic fields. This enables transformers to transmit and convert energy more efficiently, improving energy conversion efficiency.

-

03

Low hysteresis loss

The addition of silicon element to the core of silicon steel transformers can effectively reduce hysteresis loss. Hysteresis loss is the energy loss generated by magnetic materials when the magnetic field changes. Low hysteresis loss can reduce energy loss and improve the efficiency of transformers.

-

04

Corrosion resistance and wear resistance

The silicon steel transformer core has undergone surface treatment, such as painting or electroplating, and has good corrosion resistance and wear resistance performance. This helps to protect the iron core from the effects of moisture, chemicals, or mechanical wear, extending its service life.

-

05

Reducing noise and vibration

The design and structure of silicon steel transformer cores help to reduce noise and vibration. By using reasonable core geometry and clamping methods, magnetic flux leakage and core vibration can be reduced, thereby reducing the noise level of transformers and improving their stability and reliability.

-

06

Customizability

The silicon steel transformer core can be customized according to specific transformer design requirements. The shape, size, and laminated structure of the iron core can be adjusted to meet the power, frequency, and size requirements of different transformers.

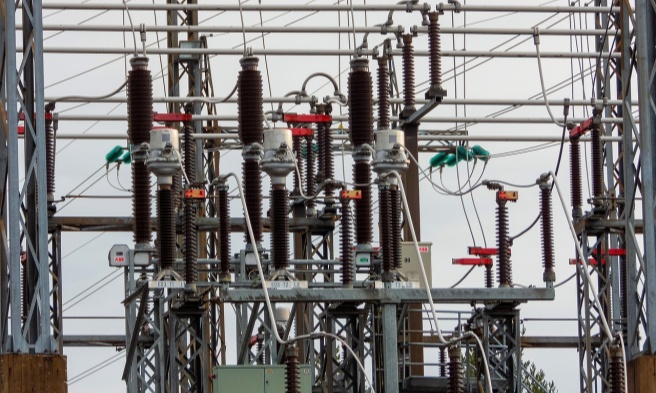

Applications

-

Power transformer

-

Distribution Transformer

-

Electric voltage regulator

-

Mid-high frequency transformer

-

APF

-

Energy Storage Power Station

-

Inverter