- Feature

- Performance

- Curve Comparison Chart

- Advantage

- Applications

- Video

Feature

Feature Description

Operating Frequency in MHz range (> 8MHz);

Cost effective low loss material;

Better DC Bias Characteristics.

Performance

High magnetic conductivity

Iron silicon aluminum magnetic cores have high magnetic conductivity, which can effectively concentrate and conduct magnetic fields. This enables it to efficiently transfer and convert electrical energy in equipment such as power transformers and inductors.

Low hysteresis loss

Hysteresis loss refers to the energy loss generated by a material when the magnetic field changes. Iron silicon aluminum magnetic cores have low hysteresis characteristics, which means they can quickly respond to changes in the magnetic field and reduce energy loss.

Good saturation magnetic induction strength

Iron silicon aluminum magnetic cores have a high saturation magnetic induction strength, which means they can store more magnetic energy in a saturated state. This is very important for applications that require high magnetic field strength, such as power transformers and motors.

Good temperature stability

Iron silicon aluminum magnetic cores have good temperature stability and can maintain stable magnetic properties at higher temperatures. This makes it suitable for applications in high-temperature environments, such as high-power power electronic devices.

Adjustable

The magnetic properties of iron silicon aluminum magnetic cores can be adjusted by changing the chemical composition of the material and the heat treatment process. This allows manufacturers to optimize the performance of magnetic cores based on specific application requirements.

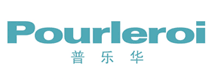

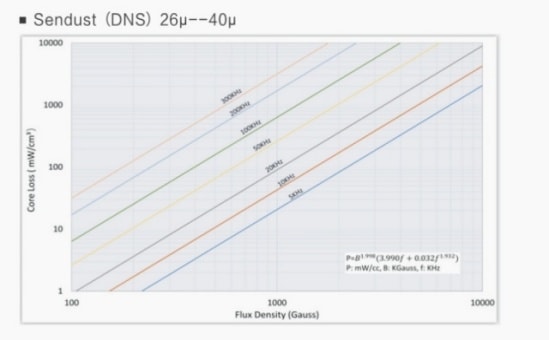

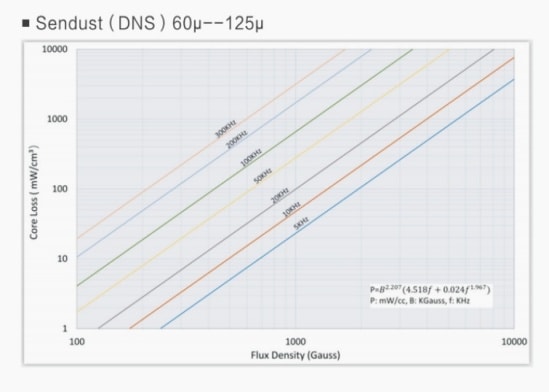

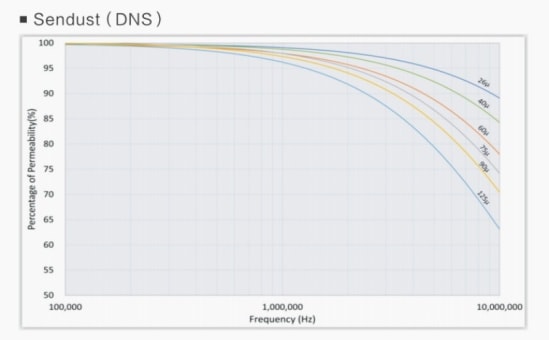

Curve Comparison Chart

Advantage

-

01

High magnetic permeability

Iron silicon powder core has high magnetic permeability, which can effectively conduct magnetic fields, provide higher inductive inductance value and lower energy loss. This makes it have excellent performance in applications such as inductors and transformers.

-

02

Low core loss

Iron silicon aluminum magnetic cores have low hysteresis characteristics, which means they can quickly respond to changes in the magnetic field and reduce energy loss. This can improve the efficiency of electronic devices and reduce energy loss.

-

03

Workability

Iron silicon aluminum magnetic core materials are easy to process and shape, and can be manufactured into various shapes and sizes of magnetic cores to meet the needs of different equipment.

-

04

Good temperature stability

Iron silicon aluminum magnetic cores have good temperature stability and can maintain stable magnetic properties at higher temperatures.This makes it suitable for applications in high-temperature environments, such as high-power power transformers and motors.

-

05

High saturation magnetic

induction intensityIron silicon aluminum magnetic cores have higher saturation magnetic induction intensity compared to traditional iron silicon magnetic cores. This means that under the same volume, it can store more magnetic energy, provide higher magnetic field strength, and is suitable for applications that require high magnetic field strength.

-

06

Low eddy current loss

Eddy current loss refers to the energy loss caused by current eddy currents in a magnetic core due to changes in magnetic field. The iron silicon aluminum magnetic core reduces eddy current losses in the material and improves energy efficiency through a special preparation process.

-

07

Adjustable

The magnetic properties of iron silicon aluminum magnetic cores can be adjusted by adjusting the chemical composition of the material and the heat treatment process. This allows manufacturers to optimize the performance of magnetic cores based on specific application requirements.

Applications

-

PC Power Supply

-

Power Adapter

-

Uninterruptible Power Supply

-

Household Appliance

-

APF

-

Energy Storage Power Station

-

Rail Transit