Magnetic components are essential in the design of efficient power systems. Whether the goal is to convert, filter, or regulate electrical energy, the choice of core material directly affects how well a system performs. Among modern materials, amorphous block cores offer a strong balance of magnetic performance, thermal stability, and energy efficiency—making them increasingly important in applications that operate at high frequencies, high temperatures, or high power levels. This article looks at how amorphous block cores work, why they matter, and where they make the biggest difference.

An amorphous block core is a soft magnetic component made from amorphous metal—a type of alloy with a disordered atomic structure. Unlike traditional crystalline materials, where atoms are arranged in a fixed pattern, amorphous metals are non-crystalline. This unique structure gives them several valuable magnetic and physical properties.

The term “block core” refers to its form. While many magnetic cores are ring-shaped or toroidal, block cores are rectangular or square-shaped, which makes them well-suited for larger devices or applications where surface mounting and modular design are important. These cores are often used in power electronics equipment that demands reliable performance in compact designs.

The most common applications of amorphous block cores include transformers, inductors, filters, and reactors—especially in systems that require high efficiency, wide frequency handling, and thermal resilience.

Amorphous block cores are chosen not just for their form factor, but for how they perform in real conditions. Their material properties provide several key performance benefits that make them a reliable solution across industrial and energy sectors.

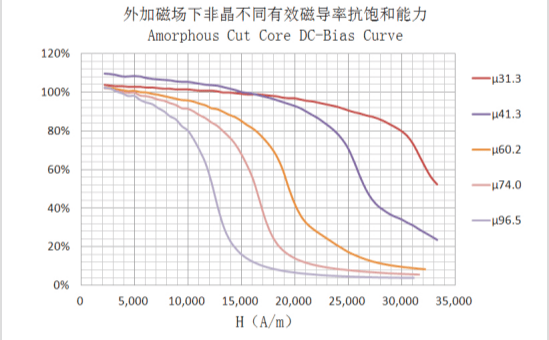

One of the first things designers look at in a core is its magnetic permeability—the ability of a material to support magnetic flux. Amorphous cores generally offer high initial permeability, which improves the coupling between windings in a transformer or inductor.

This results in better efficiency, especially in systems where energy must be transferred quickly and with minimal loss. For example, in a high-frequency inverter, high permeability reduces the size of the magnetic component without sacrificing inductance.

Core loss refers to energy lost as heat during the magnetization and demagnetization process. This includes both hysteresis loss and eddy current loss. Amorphous block cores are known for their extremely low core loss—often significantly lower than crystalline silicon steel or standard ferrite materials.

This property makes them ideal for high-efficiency applications such as switch-mode power supplies, active filters, and solar inverters, where energy loss directly affects performance, temperature rise, and long-term reliability.

High temperature environments are common in industrial power systems. Whether it's inside a solar inverter mounted on a hot rooftop, or a UPS system operating at full load, components must hold up over time.

Amorphous block cores maintain stable magnetic properties across a wide temperature range. They can be used in systems that operate above 100°C without a drop in performance. Their structure resists degradation, and they maintain consistent permeability and saturation characteristics even after long periods of thermal exposure.

One of the strongest features of amorphous material is its ability to perform across a broad range of frequencies. From 10 kHz to 100 kHz and beyond, amorphous block cores show minimal change in magnetic performance. This makes them suitable for power conversion systems, where switching frequencies vary depending on load conditions.

Many materials lose efficiency at high frequencies due to increased eddy currents. Amorphous metal, due to its thin ribbon structure and high resistivity, suppresses eddy current formation. This keeps losses low and energy delivery stable.

Saturation flux density is a key indicator of how much magnetic field a core can handle before losing effectiveness. Amorphous block cores exhibit high saturation induction, allowing them to store more magnetic energy in a smaller volume.

This enables engineers to design smaller magnetic components for high-power circuits. Whether used in a DC reactor or high-frequency filter, the core won't saturate easily under load—keeping the system stable and efficient.

It's not just about performance. Engineers consider the complete picture when selecting magnetic materials. Here's how amorphous block cores provide advantages beyond raw specs.

Because of their higher magnetic performance per unit volume, amorphous cores allow smaller component designs. A transformer or inductor using an amorphous core can meet the same electrical specs in a more compact form than one made with standard iron powder or silicon steel. This is especially important in applications like portable energy systems, modular racks, and onboard power units.

Low core loss leads directly to less heat. In dense electronics systems, even small thermal reductions matter. Using amorphous block cores means fewer demands on heat sinks, fans, and enclosures. This can also improve overall system reliability, since high temperatures accelerate component aging.

Amorphous cores are made using rapid solidification or melt-spinning techniques, which produce thin ribbons that can be cut, stacked, or molded into various forms. This flexibility supports both high-volume production and custom small-batch designs.

Block cores, in particular, can be shaped for surface-mount or frame-mounted installations, giving product designers more options in power layout.

Block-shaped cores offer strong structural integrity. They're easier to mount than toroids and are more resistant to chipping or cracking during handling. In high-vibration environments—such as rail systems or industrial motor controls—this mechanical resilience is a critical advantage.

Amorphous block cores serve a wide range of industries. They're especially valuable in systems that involve high current, frequent switching, or where efficiency and thermal limits are critical.

Solar inverters must convert DC power to AC at varying loads and frequencies. Amorphous block cores are used in reactor coils to manage current spikes and maintain output stability.

In high-speed switch-mode power supplies, filtering high-frequency noise is essential. These cores are used in input/output filters to reduce EMI without adding significant losses or heat.

UPS systems require continuous power flow, often with rapid switching and heavy load transitions. Amorphous cores in chokes and transformers help maintain power quality while minimizing energy loss during backup transitions.

Grid-tied batteries and energy storage power stations rely on compact, high-efficiency magnetic components. The low loss and thermal resilience of amorphous cores make them an ideal fit.

APF units are used to correct power quality in industrial networks. Amorphous cores ensure fast magnetic response and stability under fluctuating current loads.

Power units in rail transport must endure vibration, heat, and electromagnetic interference. Amorphous cores deliver performance while meeting strict reliability standards.

Amorphous block cores combine magnetic performance, temperature stability, and efficiency into one reliable component. Their unique properties allow them to support high-frequency, high-current systems without the compromises of traditional materials. From solar inverters to UPS modules and energy storage platforms, they serve as the silent backbone of modern power electronics. For designers seeking a proven solution across demanding applications, Pourleroi offers a full line of amorphous block cores engineered for reliable performance under real-world conditions.

For product inquiries or technical support, contact us at sales7@pourleroi.com or visit www.pourleroi.com.

By continuing to use the site you agree to our privacy policy Terms and Conditions.