From the quiet hum of your refrigerator to the smooth spin of a washing machine drum, magnetic cores are working behind the scenes to keep household appliances running efficiently and reliably. Though rarely seen, these small components play a central role in controlling power, reducing electrical noise, and ensuring stable operation across a wide range of devices. This article unpacks how magnetic cores function within everyday appliances—and why their performance matters more than most people realize.

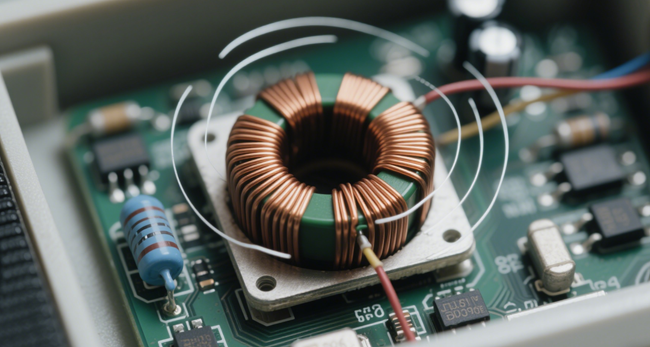

A magnetic core is a piece of ferromagnetic material—usually iron-based—that's used to guide and store magnetic energy. It often takes the form of a ring, block, or E-shaped component, and it sits at the heart of inductors, transformers, and chokes.

When electric current flows through a wire, it creates a magnetic field. But that field can be weak and messy. A magnetic core strengthens the field and keeps it where it's needed. It does this by concentrating the magnetic flux inside itself, reducing losses and improving performance.

This is especially useful in appliances that rely on AC motors, switch-mode power supplies, and power factor correction circuits. Without magnetic cores, these devices would be larger, less efficient, noisier, and more prone to failure.

Not every part of an appliance needs a magnetic core. But many of the parts that manage energy do. Here's where they typically show up.

Modern air conditioners and fridges use inverter technology to adjust compressor speed based on demand. This reduces energy consumption and keeps temperatures more stable. But inverters require fast switching and precise voltage control, which generates electromagnetic interference (EMI).

Magnetic cores are used in EMI filters and smoothing inductors in the control board. They help shape the flow of power and block noise from leaving the device. This keeps your air conditioner from interfering with your TV or Wi-Fi—and helps it pass government standards for electromagnetic compatibility.

These appliances use motors, sensors, and power circuits that operate under variable loads. Magnetic cores help stabilize those circuits. Toroidal chokes wrapped around cable bundles reduce conducted noise, while motor drive circuits rely on filter inductors to control torque and speed smoothly.

Without magnetic cores, your washing machine might whine during spin cycles or trip your circuit breaker unexpectedly. The core helps it run quietly, safely, and with fewer resets or faults.

High-frequency energy is common in kitchen appliances. Microwave ovens use magnetrons to generate electromagnetic waves. Induction cooktops use magnetic fields to heat cookware. Coffee machines often use switching power supplies and sensors to control heating precisely.

All these functions involve rapid changes in current. Magnetic cores help limit the ripple and control the power signal. This means fewer spikes, less internal heat, and safer operation for the electronics inside.

Even devices that don't seem powerful—like ceiling fans or smart speakers—often contain motor drivers or adapters that benefit from magnetic cores. Ferrite beads and powdered iron chokes manage small surges and filter unwanted signals. This protects sensitive logic chips and extends device life.

Whether it's a fan's speed controller or a TV's internal power board, magnetic cores keep the electronics stable and cool.

Not all magnetic cores are made the same. The best ones for household use must combine several features:

High magnetic permeability: This allows efficient energy transfer in transformers and inductors, helping reduce overall size.

Low core losses: Appliances often run for hours. A good core generates less heat, reducing the risk of thermal fatigue and saving energy.

Resistance to DC bias: Many circuits carry a mix of AC and DC current. Magnetic cores must stay stable under bias to maintain inductance.

Thermal stability: Appliances operate in variable environments—kitchens, bathrooms, and garages. A stable core won't drift or crack under heat.

Material selection plays a big role. Ferrite is common and cost-effective but can saturate or become brittle under mechanical stress. High-flux powdered cores offer higher saturation and better bias handling. Sendust cores add good temperature performance and soft saturation. The right core depends on the size, cost, and behavior required.

Appliance efficiency isn't just about motors or heating elements. It's also about how energy is moved and shaped inside the circuit. Magnetic cores determine how effectively a system can filter, store, or convert electrical energy.

Take an induction cooker, for instance. It needs to deliver high-frequency current to the coil under the cooking surface. But those signals can bounce, spike, or fall apart without proper filtering. A well-designed magnetic core ensures clean waveforms, reducing heat in the electronics and improving precision cooking.

In a refrigerator inverter board, a high-quality core allows for tighter speed control of the compressor. This lowers power usage during idle operation and reduces cycling stress on the motor.

Across dozens of appliance categories, these kinds of improvements—small on their own—add up to big gains in durability and energy consumption.

While magnetic cores work behind the scenes, their benefits are easy to notice.

For consumers, this means:

Quieter operation

Lower energy bills

Longer-lasting appliances

Fewer electrical surges and flickers

For manufacturers, magnetic cores offer:

Easier compliance with EMI standards

Reduced warranty claims due to electrical failure

Higher energy efficiency ratings (such as Energy Star)

Smaller PCB footprints and lighter components

In a competitive appliance market, these advantages matter. A small increase in efficiency can be the difference between a B-label and an A++ product. A quieter fan motor can be a reason a consumer chooses one air purifier over another.

Appliances don't operate in labs. They run in hot kitchens, damp laundry rooms, and dusty garages. Magnetic cores used in these environments must be resilient.

This is why many appliance designers avoid brittle materials or unsealed components. Cores exposed to vibration must be mechanically stable. Those near heating elements must resist long-term thermal drift. And in smart appliances with wireless modules and microcontrollers, the core must suppress noise without affecting communication.

Good magnetic cores are tested for these real-world conditions. Their thermal curves, permeability retention, and mechanical strength are verified before deployment. This ensures that once placed in a circuit, they behave as expected—day after day, year after year.

Despite their importance, magnetic cores aren't talked about often. That's because they're passive components. They don't blink, spin, or make noise. But just like a building's foundation, their strength affects everything above them.

When a power supply fails, the fault isn't always visible. But engineers often trace it back to saturation, EMI, or overheating tied to a poorly chosen magnetic core. This is why appliance designers invest time selecting the right material, shape, and specs for each function.

As electronics become more compact and more connected, magnetic cores will remain essential for controlling power safely and efficiently.

Magnetic cores may not be visible when you use your coffee machine or start the dishwasher, but they're working in the background every second. By guiding magnetic energy, reducing noise, and enabling efficient power conversion, they help modern appliances run better in every way. For manufacturers seeking dependable magnetic solutions tailored for home electronics, Pourleroi offers a diverse range of high-performance cores designed to meet today's real-world challenges.

For more details, contact us at sales7@pourleroi.com or visit www.pourleroi.com.

By continuing to use the site you agree to our privacy policy Terms and Conditions.