In the rapidly advancing field of electrical engineering, the evolution of material science has opened the door to groundbreaking innovations. Amorphous cores, a novel type of magnetic material, are making waves in the realms of power electronics and electromagnetic compatibility with their distinctive physical properties and superior performance.

Amorphous cores , also known as nanocrystalline cores, are a class of non-crystalline materials that exhibit unique magnetic characteristics. Unlike traditional crystalline cores, which have a well-defined atomic structure, amorphous cores have a random atomic arrangement, endowing them with exceptional properties that are highly sought after in modern applications.

1. High Magnetic Flux Density: Amorphous cores boast a high saturation magnetization, which allows for a greater magnetic flux density. This translates to smaller and lighter components in transformers and inductors, making them ideal for compact electronic devices.

2. Low Core Loss: One of the most significant advantages of amorphous cores is their low core loss, particularly in high-frequency applications. This characteristic results in improved efficiency and reduced energy consumption, which is paramount for today's energy-conscious society.

3. Excellent Frequency Response: The amorphous structure provides a superior frequency response compared to crystalline materials. This makes amorphous cores suitable for high-frequency applications, such as in switch-mode power supplies and high-speed data transmission systems.

4. High-Resistivity: The high electrical resistivity of amorphous cores reduces eddy current losses, which is particularly beneficial in applications where heat dissipation is a concern.

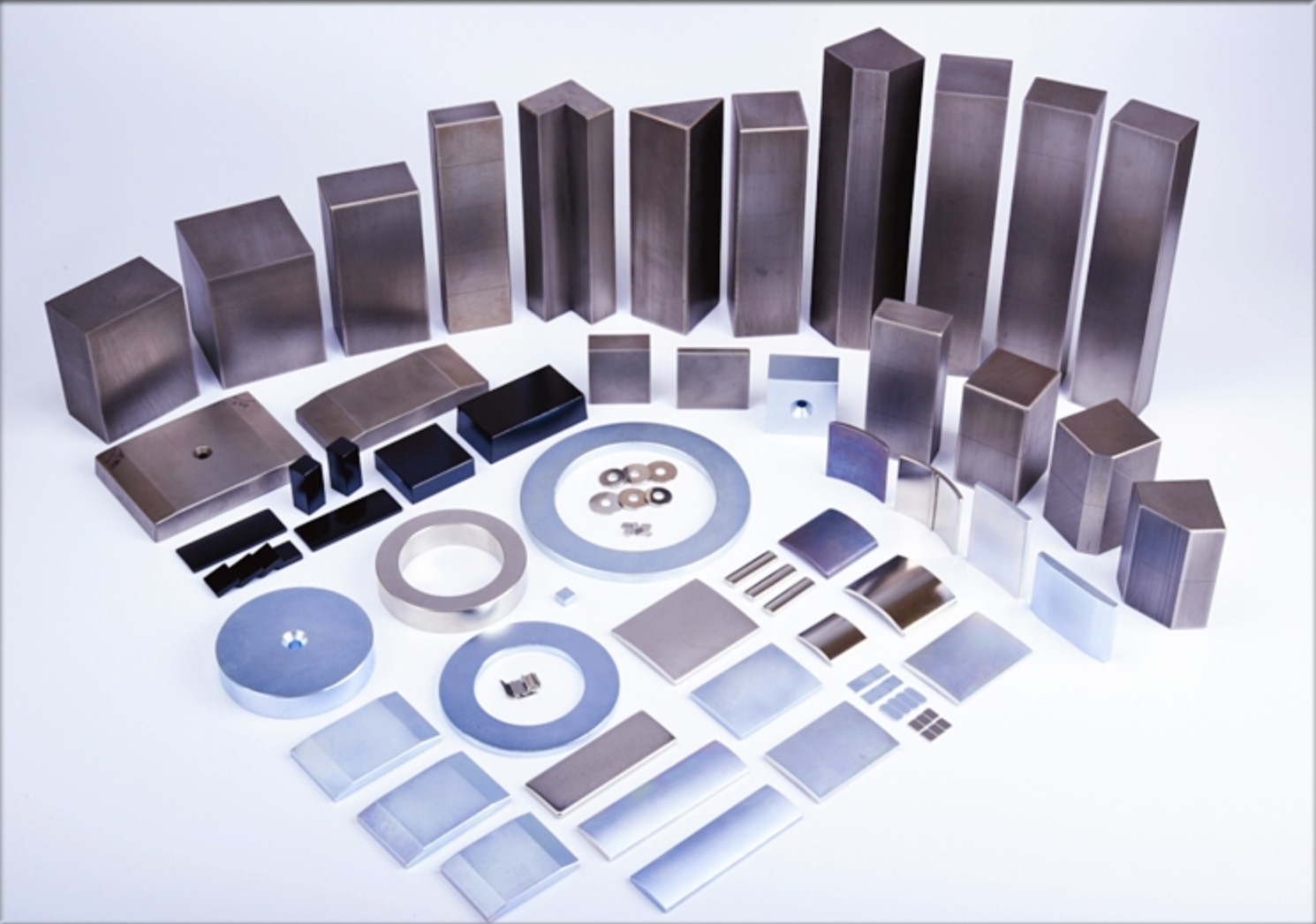

5. Mechanical Flexibility: Amorphous cores can be easily cut and shaped, allowing for greater design flexibility and the ability to create custom components tailored to specific applications.

The versatility of amorphous cores has led to their widespread adoption across various industries:

1. Power Electronics: In power electronics, amorphous cores are used in transformers and inductors for switch-mode power supplies, benefiting from their high efficiency and low core loss at high frequencies.

2. Telecommunications: The high-frequency performance of amorphous cores makes them perfect for use in telecommunication equipment, such as signal transformers and filters.

3. Renewable Energy: In the renewable energy sector, amorphous cores are utilized in inverters for solar panels and wind turbines, where their efficiency and durability are critical.

4. Automotive Industry: The automotive industry leverages amorphous cores for their compact size and high performance in power steering systems, ignition coils, and various sensor applications.

5. Aerospace and Defense: Due to their high stability and performance over a wide range of temperatures, amorphous cores are also used in aerospace and defense applications, such as in satellite power systems and military-grade electronics.

As the demand for energy-efficient and high-performance electronic components continues to rise, the role of amorphous cores in the industry is expected to grow. Ongoing research and development are focused on enhancing the properties of these materials and expanding their applications.

While amorphous cores offer numerous benefits, there are challenges to their widespread adoption:

1. Cost: The production of amorphous cores can be more expensive than traditional materials, which can be a barrier for some applications.

2. Material Sensitivity: Amorphous materials can be sensitive to mechanical stress and temperature changes, requiring careful handling and design considerations.

3. Manufacturing Techniques: Improvements in manufacturing techniques are necessary to reduce costs and make amorphous cores more accessible to a broader range of applications.

Amorphous cores represent a significant leap forward in material science, offering a combination of properties that are unmatched by traditional magnetic materials. As technology progresses and the demand for efficient, high-performance electronic components soars, amorphous cores are poised to play a pivotal role in shaping the future of electrical engineering. With continued innovation and development, these advanced materials will undoubtedly contribute to a more efficient and sustainable world.

By continuing to use the site you agree to our privacy policy Terms and Conditions.