High-performance magnetic materials are at the core of modern power systems. Whether used in electric vehicles, telecom equipment, or energy storage systems, these components shape how efficiently devices operate under load. Among the many magnetic options, DNH High Flux Cores offer a unique blend of material strength, design flexibility, and electromagnetic performance that makes them stand out in a competitive field. This article examines what sets them apart—starting from their composition and continuing through their applications across multiple industries.

In power electronics, space is often limited, but energy demands are increasing. Magnetic components must carry higher currents, handle temperature swings, and fit into tighter spaces—all while minimizing losses. High flux cores are designed to meet these demands. Their higher saturation flux density enables them to store more magnetic energy in a smaller volume than ferrite or traditional iron powder cores.

This makes them particularly valuable in switching power supplies, DC-DC converters, and other compact designs where conventional cores fall short. Instead of simply making a transformer bigger to accommodate current, designers can use high flux cores to keep size low and efficiency high. The DNH series builds on this principle with a refined alloy formula and precise manufacturing techniques.

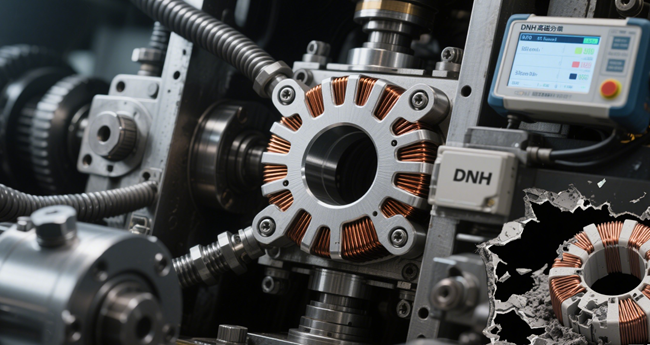

A DNH High Flux Core is a soft magnetic component made by compacting powdered metal—specifically a blend of nickel and iron—into a dense, toroidal or block-shaped form. Unlike laminated silicon steel or brittle ferrite, this material has both mechanical robustness and excellent magnetic stability. The powder composition is engineered to achieve a high saturation flux density, typically around 1.5 Tesla.

This makes DNH cores ideal for applications where inductors and transformers operate near the limits of magnetic flux. When a current passes through the winding, the magnetic field increases until the core material saturates. A higher saturation point allows more current to pass before that happens, making the design more efficient and less prone to overheating.

The success of a magnetic core depends heavily on what it's made of. DNH cores are built from a carefully balanced 50/50 mix of nickel and iron powders. These particles are insulated and bonded with a high-temperature-resistant resin, which forms a stable and durable core once compressed.

This material combination offers several distinct advantages:

High saturation flux density: More than double that of ferrite, allowing for compact, high-power designs.

Strong DC bias capability: Maintains inductance under large DC currents without collapsing, unlike ferrite materials.

Thermal stability: The cores remain magnetically stable even in environments exceeding 125°C.

Low loss profile: Reduced core loss from both hysteresis and eddy currents, especially important at medium to high frequencies.

Together, these traits give designers more flexibility. They don't have to compromise between size, performance, and efficiency—they can optimize all three at once.

Not all magnetic components share the same geometry, and DNH cores account for that. The product line includes a wide variety of shapes and sizes that support different use cases. Some are standard, while others can be customized depending on application demands.

Common DNH forms include:

Toroidal cores: Ideal for inductors, chokes, and EMI filters due to their closed magnetic path.

EER and EQ shapes: Often used in transformers where bobbin-based windings are preferred.

LP blocks and customized formats: Suitable for planar magnetic designs and surface-mounted modules.

The variety isn't just for convenience. The ability to choose different shapes means engineers can reduce leakage inductance, minimize radiated emissions, and fit cores into tight mechanical spaces—all while achieving the required magnetic performance.

Performance in controlled lab settings is one thing. Reliability in actual working environments is another. DNH High Flux Cores are built for both. Their ability to manage higher current densities without physical deformation or magnetic collapse gives them an edge in continuous operation scenarios.

In converters and power supply modules, for example, inductors are constantly switching. The magnetic core must absorb energy, release it, and repeat the cycle thousands of times per second. Ferrite cores often exhibit saturation or heat buildup under such conditions. DNH cores, on the other hand, tolerate higher magnetic fields without losing their inductive value.

This reliability extends beyond temperature and current. Because of the uniform distribution of magnetic particles and the robust resin bonding, these cores are less susceptible to mechanical stress or vibration damage. That's particularly useful in environments such as automotive power systems or industrial machinery where physical durability matters.

Thermal performance is a major design constraint in modern power systems. Every watt of energy lost as heat requires additional thermal management. Cores that generate less heat directly reduce cooling costs and improve long-term system stability.

DNH High Flux Cores help address this by exhibiting lower core loss across a wide range of frequencies. While iron powder cores suffer from eddy currents and ferrites lose permeability at high temperatures, the DNH material retains its characteristics in real-world operating conditions.

For example, in a 100kHz switching converter, the right DNH core can maintain low losses even with moderate ripple currents and elevated ambient temperature. This allows for compact layouts and passive cooling solutions that would otherwise be unfeasible.

DNH High Flux Cores are used wherever magnetic efficiency and compact power conversion are required. That includes some of the most challenging electrical environments.

Common applications include:

Electric vehicle powertrains and onboard chargers

Telecom base stations and 5G network power modules

Solar inverters and hybrid energy systems

Data center power delivery and rack-mounted UPS units

Railway traction converters and auxiliary power supplies

Industrial automation and robotics power modules

Each of these fields requires not just strong magnetic performance, but also durability, temperature tolerance, and a compact form. DNH cores are chosen not because they are generic—but because they meet very specific design criteria.

Material alone doesn't make a great core—manufacturing consistency does. DNH cores undergo a tightly controlled production process that includes powder mixing, molding, thermal treatment, and final quality inspection.

Dimensional tolerances are kept tight to ensure the magnetic circuit functions as modeled. Coating and insulation layers are applied evenly to prevent short circuits between windings. Magnetic properties are measured to confirm that the core's behavior aligns with its electrical specification.

This level of control reduces design iteration during product development and ensures the same core behaves identically in every unit shipped. For volume manufacturers, that means lower rejection rates and higher customer satisfaction.

DNH High Flux Cores bring together advanced material science and practical engineering to meet the evolving demands of high-performance power systems. Their ability to deliver high magnetic saturation, thermal stability, and design flexibility makes them an essential component in compact, efficient electronics. For manufacturers and engineers seeking proven reliability across industries such as EVs, energy systems, and industrial automation, the DNH series from Pourleroi offers a trusted magnetic solution backed by consistent quality and specialized expertise.

For inquiries or technical support, reach out to us at sales7@pourleroi.com or visit www.pourleroi.com.

By continuing to use the site you agree to our privacy policy Terms and Conditions.