Welcome:Pourleroi

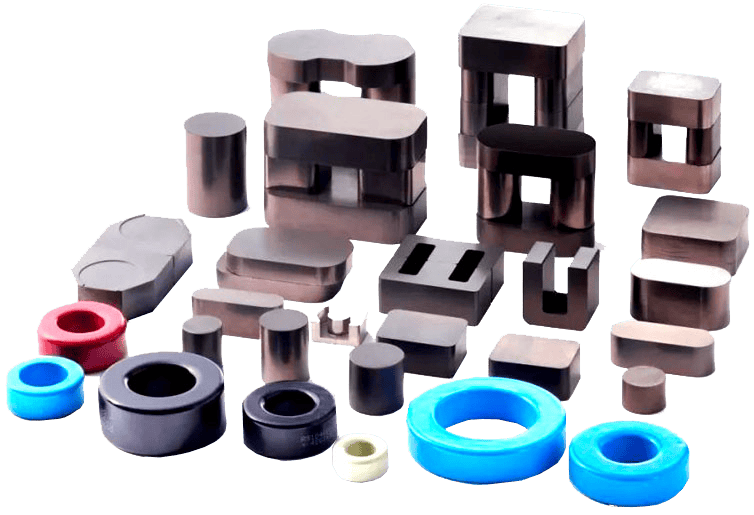

| Core Type | Industrial Automation Application | Key Benefits and Features |

| Toroidal | Power supplies, transformers, inverters | High efficiency, small size, low electromagnetic interference |

| E-shaped | Large power electronics, industrial equipment | Easy to put together, handles more power |

| U-shaped | Transformers, chokes, reactors | Custom magnetic features, flexible design |

| Core Type | Material Composition | Frequency Suitability | Typical Applications | Customer-Identified Best Use Cases |

| Powdered Iron | Iron powder with insulating material | Good at high frequencies | Inductors, transformers | High-frequency, flexible shapes, complex circuits |

| Ferrite | Ferrite materials | High-frequency | Transformers, inductors | High-frequency, low core loss |

| Laminated Steel | Silicon steel sheets | Low-frequency | Power transformers, motors | Low-frequency, high-efficiency transformers |

By continuing to use the site you agree to our privacy policy Terms and Conditions.