You can lower energy loss in modern transformers by using amorphous cores. These cores do not have a crystal structure. They also have strong magnetic properties. This helps reduce both hysteresis and eddy current losses. Look at the data in the table below:

|

Core Material Type |

Reduction in Core Loss Compared to Silicon Steel |

Efficiency Improvement |

|---|---|---|

|

Conventional Silicon Steel |

Baseline (100%) |

Baseline |

|

Amorphous Alloys |

About 60–70% less |

About 1% to 2% more |

|

Nanocrystalline Material |

Even less core loss than amorphous alloys |

More efficiency gains |

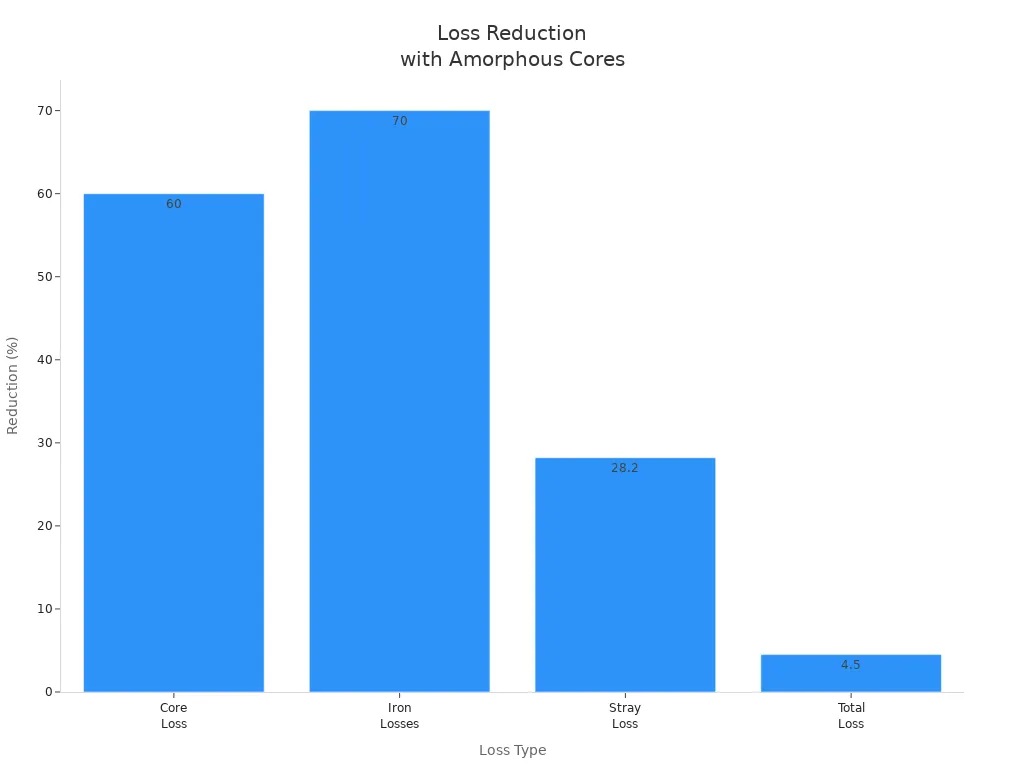

Amorphous cores help transformers lose less energy. They can cut energy loss by 70-80%. This makes transformers work better and saves money. Their special random atomic structure is important. The thin ribbon shape also helps. These features lower heat from hysteresis and eddy currents. Transformers with amorphous cores last longer. They stay cooler and need less fixing than silicon steel cores. Using these transformers is good for the environment. They waste less energy and make fewer greenhouse gases. These transformers work in many places. You can find them in homes, factories, solar farms, and electric car charging stations.

Not all the electrical energy in a transformer goes to the output. Some energy turns into heat inside the core. These are called core losses or iron losses. There are two main types: hysteresis loss and eddy current loss.

Here is a table that shows these losses:

|

Core Loss Type |

Description |

How You Measure It |

|---|---|---|

|

Hysteresis Loss |

Heat made when the core’s magnetism changes back and forth. |

Check by running the transformer with no load and measuring the input power. |

|

Eddy Current Loss |

Heat from small currents moving inside the core as the magnetic field changes. |

Use thin, laminated sheets to lower this loss; measured with no-load loss. |

You might also hear about flux loss. This happens when some magnetic lines leave the core and go through the air. Flux loss is not a main core loss, but it can still affect how well the transformer works.

Tip: Core losses happen even if the transformer is not powering anything. That is why they are called no-load losses.

Core losses are important for transformer efficiency. When core losses turn energy into heat, you lose useful power. The transformer then needs more energy to do its job.

Studies show that using better core materials, like amorphous metals, can cut core losses by up to 70–80%. This means higher efficiency and lower energy bills. For example, new transformers can lose up to 30% less power than old ones. This matters a lot for renewable energy, where saving power is important.

Lower core losses mean:

Less heat inside the transformer

Equipment lasts longer

Lower costs to run

Power stays steady, which helps solar and wind energy

Choosing transformers with advanced core materials saves energy and helps the environment.

To see why amorphous cores help, look at their structure. The atoms in amorphous core materials are arranged randomly. This happens because the metal cools very fast, about a million degrees each second. The atoms freeze before they can line up in a pattern. They stay mixed up instead of forming neat rows. Silicon steel cools slowly, so its atoms form a repeating pattern with clear lines.

Amorphous cores do not have these lines, called grain boundaries. This gives them special features. These materials are made into very thin ribbons, about 20 to 30 micrometers thick. Thin ribbons help stop unwanted currents inside the core. Amorphous materials also do not melt at one sharp temperature. They change from solid to liquid slowly, which is called a glass transition.

Here is a table that compares the magnetic properties of amorphous cores and other types:

|

Property |

Amorphous Cores |

Other Core Types (e.g., Ferrite, Silicon Steel) |

Impact on Energy Losses and Efficiency |

|---|---|---|---|

|

Core Loss |

Very low (65-75% less than silicon steel) |

Higher |

Significantly reduces wasted energy and heat generation |

|

Magnetic Permeability |

High, stable under various conditions |

Lower, affected by air gaps and manufacturing |

Improves magnetic energy handling, reducing losses |

|

Saturation Induction |

High |

Moderate |

Allows operation at higher flux densities without saturation |

|

Frequency Response |

Wide frequency range, good at high freq |

Narrower frequency range |

Enables efficient operation in high-frequency applications |

|

Temperature Stability |

Stable across wide temperature range |

Variable |

Maintains consistent low losses in diverse environments |

Note: The random atomic structure and thin ribbon shape of amorphous cores help transformers lose less energy.

Amorphous cores help cut down on energy losses in transformers. They lower both hysteresis and eddy current losses. These are the main ways transformers waste energy.

The very thin ribbons in amorphous cores make it hard for eddy currents to form. Eddy currents are small loops of electricity that turn into heat. Thin ribbons break up these loops, so less energy is wasted.

In amorphous cores, magnetization mostly happens by rotation. It does not need to move domain walls much. This means it takes less energy to change the magnetic direction, so hysteresis loss is lower.

Amorphous cores have a magnetostriction constant close to zero. This means there is less stress inside the material. The magnetic structure stays even, so hysteresis losses are even lower.

Amorphous cores also have high magnetic permeability and low coercive force. These features help the core react quickly to changing magnetic fields. This is important for transformers that work at different frequencies. Amorphous cores work well at many frequencies and temperatures, so they are reliable in many places.

Many tests and experiments show these loss reduction effects. Transformer prototypes with amorphous cores have much lower core and copper losses. They also make less vibration and noise. Scientists use models like the Jiles–Atherton model to predict how these cores act. Real tests show the predictions are correct.

Discover the superior performance of Pourleroi's Amorphous Cores and enhance your transformer efficiency today!

Using amorphous cores in transformers gives you higher efficiency, less heat, and longer life for the equipment. These good results come from the special structure and magnetic features of the material.

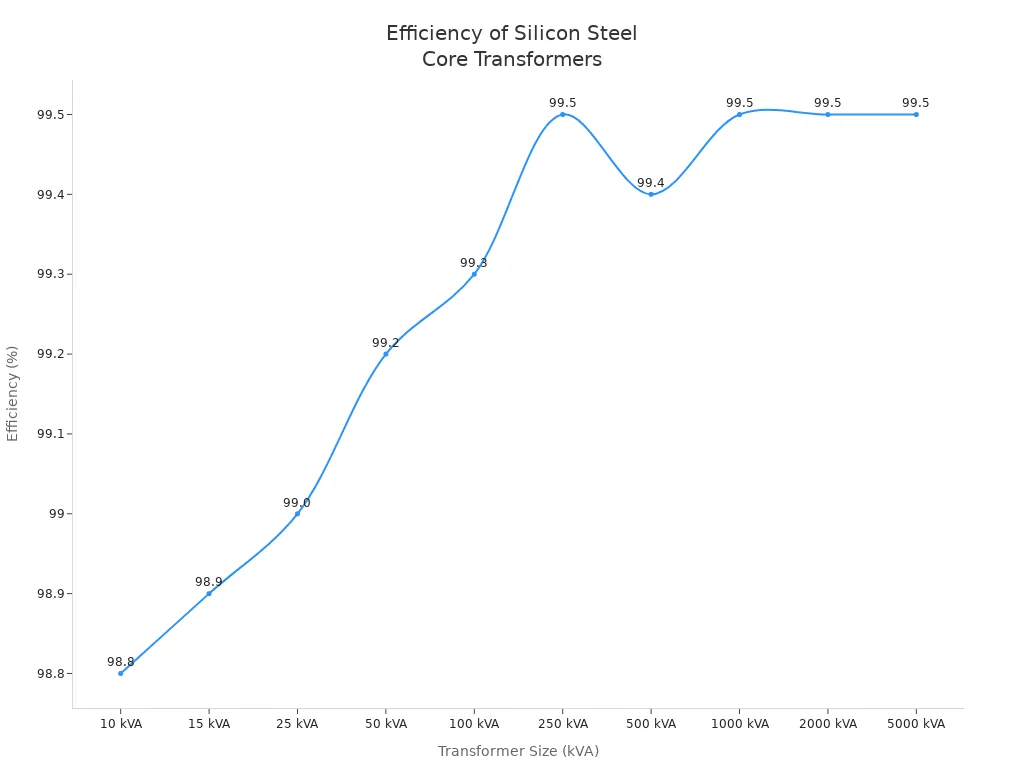

When you look at transformer cores, you notice big differences in how well they work. Silicon steel cores have been used for a long time. They work well, especially in big transformers. For example, a 1000 kVA silicon steel core transformer can be about 99.5% efficient. The table below shows how the size of the transformer changes its efficiency:

|

Transformer Size (kVA) |

Efficiency (%) |

|---|---|

|

10 |

~98.8 |

|

50 |

~99.2 |

|

100 |

~99.3 |

|

1000 |

~99.5 |

|

5000 |

~99.5 |

Amorphous cores lose even less energy, especially when not working at full power. At 20% load, an amorphous core transformer wastes about half as much energy as a silicon steel core transformer. This means less energy is lost when the transformer is not being used a lot. The table below shows how much energy is lost:

|

Transformer Type |

No-Load Loss (W) |

Load Loss (W) |

Efficiency at 20% Load (%) |

Loss Reduction Compared to Silicon Steel |

|---|---|---|---|---|

|

Silicon Steel Core |

~430 |

~4600 |

99.69 |

Baseline |

|

Amorphous Core |

~194 |

~4600 |

99.81 |

50% lower at 20% load |

Note: Amorphous cores help save more energy in places like homes or small shops where transformers do not run at full power.

You can see how amorphous cores help in real projects. When a company changed a 1000 kVA transformer to one with an amorphous core, it lost 65% less energy when not in use. This saved about 5,000 kWh of energy every year. In another example, a 10 MVA substation transformer upgrade made load losses drop by 12%. This saved over 100,000 kWh each year.

Here are some real improvements:

No-load losses can go down by up to 70% after using amorphous cores.

Some projects have 25% less total transformer loss.

You get your money back faster, sometimes in just four years.

Amorphous core transformers also need less fixing. They make less heat, so the insulation lasts longer. Many use dry-type insulation, so you do not have to worry about oil leaks. The strong core material can handle stress and shaking, so there are fewer repairs.

Even though amorphous core transformers cost more at first, you save money later. You pay less for energy and repairs over the life of the transformer. These savings also help the planet by wasting less energy and making less pollution.

Transformers with amorphous cores help save a lot of energy. The U.S. Department of Energy says new rules can cut energy loss by up to 30% in some transformers. These savings could add up to $15 billion over 30 years. They could also stop 340 million metric tons of carbon from going into the air. Using less electricity means you pay less for power. It also helps the power grid work better. Amorphous cores help by wasting less energy, especially when transformers are not working at full power.

Amorphous core transformers are good for the environment in many ways:

They use a special metal that lowers core losses, so less energy turns into heat.

When less energy is wasted, power plants burn less fuel. This means fewer greenhouse gases go into the air.

Making amorphous cores uses less energy and makes less pollution than making steel cores.

These transformers last longer and can be recycled, so there is less trash.

Amorphous cores do not have harmful chemicals and follow strict environmental laws.

Picking amorphous core transformers helps keep the air clean and fights climate change.

You can find amorphous core transformers in many places. They give steady power to factories, data centers, and hospitals. They are also used in solar and wind farms, where power levels change a lot. Utilities use them to make power grids better and more reliable. In transportation, they help run trains and charge electric cars.

Pourleroi is a trusted company that makes amorphous cores. The company has ISO9001 and CE certificates, which show it cares about quality and safety. Pourleroi’s products are used in solar systems, electric cars, trains, and smart power grids. You can get custom cores for special needs, like high currents or small spaces. Pourleroi’s cores work well, last long, and are made to protect the environment.

You can see that new materials help transformers use less energy. The table shows that these cores lower core losses by up to 80%. Transformers with these cores save thousands of kilowatt-hours every year. They also last longer than old ones.

|

Feature |

Traditional Core |

Amorphous Core |

|---|---|---|

|

Core Loss Reduction |

Baseline |

Up to 70-80% lower |

|

Annual Energy Savings |

Baseline |

15,000-30,000 kWh |

|

CO₂ Emission Reduction |

Baseline |

10-20 tons/MVA/year |

More companies pick these cores for better efficiency.

People want energy-saving products, and new rules help spread them everywhere.

You can count on suppliers like Pourleroi for good, efficient transformers in the future.

The atoms in amorphous cores are mixed up. Regular cores have atoms lined up in rows. This mixed-up structure helps save more energy.

Yes, you can use them in many places. They work in homes, factories, solar farms, and charging stations. You get better efficiency and lose less energy everywhere.

You help the planet by using less power. Amorphous cores waste less energy, so power plants burn less fuel. This means fewer greenhouse gases go into the air.

They cost more at first. But you save money over time because they use less energy and last longer. Many people think the savings are worth the higher price.

By continuing to use the site you agree to our privacy policy Terms and Conditions.