You can find Iron Silicon Cores inside many electrical machines. These cores have iron and silicon mixed together. This mix gives them special abilities.

|

Property |

Description |

|---|---|

|

Magnetic Permeability |

High—magnetic fields move through them easily |

|

Core Loss |

Low—helps save energy in things like transformers and motors |

|

Electrical Resistivity |

High—stops extra currents and heat from forming |

These features help make transformers and motors work well. They also help save energy and make machines more reliable.

Iron Silicon Cores mix iron and silicon together. This helps their magnetic properties get better. They work well in transformers and motors. These cores have low core loss. This means they save energy and keep devices cool when working. Iron Silicon Cores have high electrical resistivity. This lowers eddy currents. So, less energy is wasted and efficiency goes up. The silicon in the cores makes them stronger and tougher. This helps them handle stress and last longer in electrical devices. Iron Silicon Cores are useful in many ways. They can be used in relays, solenoids, and other electrical devices. This makes sure they work well and are reliable.

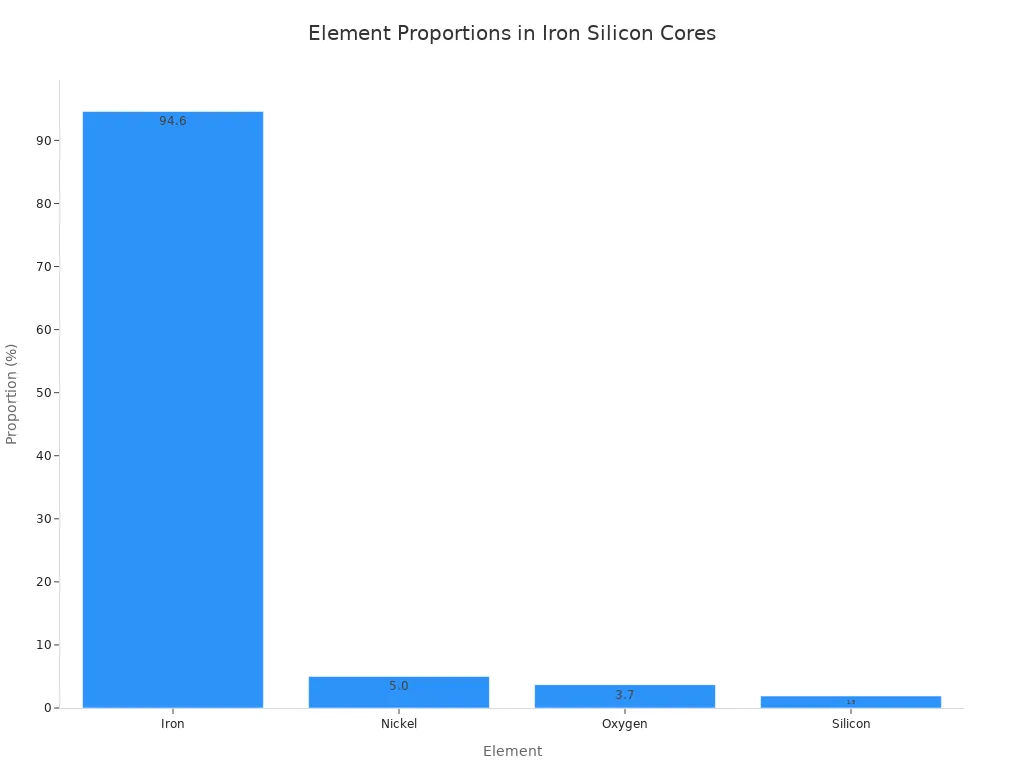

Iron Silicon Cores are made from a mix of elements. Iron is the main part. Other elements are also important. Here is a table that shows how much of each element is in the core:

|

Element |

Proportion (%) |

|---|---|

|

Iron |

~94.6 |

|

Nickel |

~5.0 |

|

Oxygen |

3.7 |

|

Silicon |

1.9 |

|

Sulfur |

0.0 |

|

Carbon |

0.0 |

Silicon is very important in these cores. Adding silicon changes how the atoms are arranged. This makes the core stronger and harder. If you add more silicon, like from 3% to 5%, the core gets stronger. But it also becomes less bendable. Here is a table that shows what happens when you change the silicon amount:

|

Silicon Content (%) |

Lattice Distortion Degree |

Effect on Strength and Hardness |

Effect on Plasticity and Toughness |

|---|---|---|---|

|

2.92 |

0.06 |

Increased |

Relatively unchanged |

|

4.59 |

0.22 |

Further increased |

Decreased |

Iron Silicon Cores have special magnetic abilities. Silicon makes the core easier to magnetize and demagnetize. It also raises resistivity, which helps stop extra currents. This saves energy.

Silicon changes how atoms are lined up, so the core is easier to magnetize.

Higher resistivity means less energy is lost from eddy currents.

Lower magnetostriction keeps the core quiet and stable when magnetized.

Tip: These features help transformers and motors work better and make less noise.

You might wonder how Iron Silicon Cores compare to other materials. Here are some important facts:

Amorphous cores have even higher magnetic permeability at high frequencies.

Silicon steel works best at normal power frequencies like 50 or 60 Hz.

Amorphous metals lose less energy at higher frequencies.

Iron Silicon Cores are a good choice for most electrical machines. They balance cost, strength, and magnetic performance.

Iron Silicon Cores have many useful features. These features make them important in electrical devices. You can find these properties in machines around you.

Key Highlights:

High magnetic permeability

High saturation magnetization

High electrical resistivity

Low core loss

Near zero magnetostriction

Magnetic permeability shows how easily something gets magnetized. Iron Silicon Cores have high magnetic permeability. This means magnetic fields move through them easily. Transformers and motors work better with these cores. High permeability helps the core react fast to changes. It also lets you build smaller, more efficient devices.

Permeability tells us how much magnetization a material can get. Iron Silicon Cores help devices use magnetic fields well. This means less energy is wasted. Transformers use high permeability to move energy between coils. Fewer coils are needed, so devices can be smaller.

High magnetic permeability helps motors and transformers perform better.

These cores guide magnetic flux well, making designs smaller.

Silicon steel, a kind of Iron Silicon Core, has low hysteresis loss. This means less energy is lost when working.

Core loss is energy lost as heat in a changing magnetic field. You want core loss to be low to save energy. Iron Silicon Cores have low core loss at common frequencies.

|

Frequency (kHz) |

Core Loss (kW/m³) |

Magnetic Flux Density (T) |

Silicon Content (wt%) |

|---|---|---|---|

|

10 |

400 |

0.2 |

N/A |

|

50-60 |

70-200 |

N/A |

N/A |

|

kHz to MHz |

70-800 |

N/A |

N/A |

|

50 |

632 |

0.1 |

6.5 |

|

50 |

610 |

0.1 |

3.0 |

Core loss stays low at normal power frequencies. This keeps devices cool and efficient. Silicon in the core helps lower these losses. Silicon raises electrical resistivity, which stops eddy currents. Eddy currents waste energy in AC devices.

Electrical resistivity shows how well a material blocks electric current. Iron Silicon Cores have high resistivity because of silicon. High resistivity cuts down on eddy current losses. Eddy currents are loops of electric current inside the core. They waste energy as heat.

Silicon increases magnetic conductivity and electrical resistance.

Adding silicon can make iron five times more resistant.

Higher resistivity means fewer eddy currents and less wasted energy.

For example, CarTech Silicon Core Iron "A" has 25 micro-ohm-centimeters resistivity. Regular electrical iron has only 13. Some special alloys reach up to 58 micro-ohm-centimeters. This makes Iron Silicon Cores great for AC devices, where saving energy matters.

Silicon in the steel raises electrical resistivity. This helps stop eddy currents from forming.

Using Iron Silicon Cores means your devices lose less energy as heat. This makes them more efficient.

Mechanical strength is another important property. Iron Silicon Cores have good tensile strength and ductility. They can handle stress and strain without breaking. These cores last a long time in electrical devices, even in tough places.

Iron Silicon Cores also give good electrical insulation and electromagnetic shielding. These features protect the core and the device. Silicon in the alloy makes the core more stable. Compared to other materials, Iron Silicon Cores handle more stress and vibration. This makes them a great choice for devices that need to work for many years.

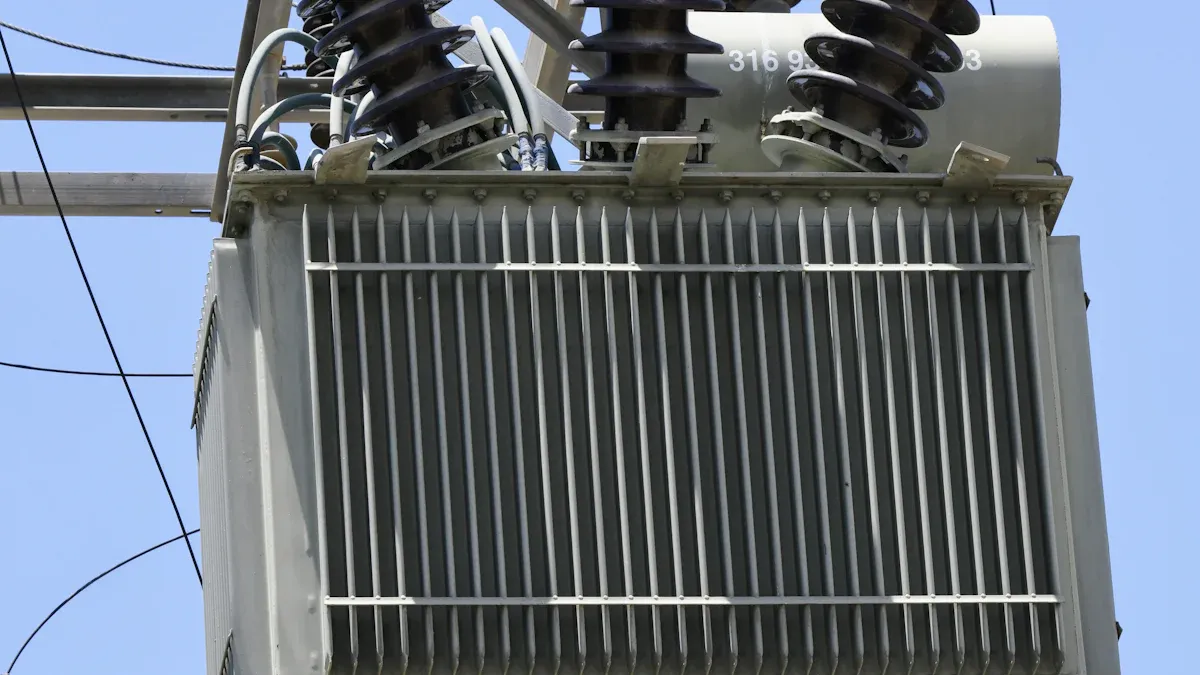

Transformers are in many places, like power stations and chargers. Iron Silicon Cores help transformers work better and save energy. They let magnetic fields move easily through the core. This helps transformers send energy between coils with less loss. Grain-oriented silicon steel lines up the grains inside the core. This lowers hysteresis losses. Transformers stay cool and work well, even when the load changes. Silicon steel keeps transformers reliable in different temperatures. You get better efficiency and performance, especially in power transformers.

Tip: Iron Silicon Cores help transformers use less energy and last longer.

Motors use Iron Silicon Cores to change electricity into movement. These cores keep the magnetic circuit steady, so motors run smoothly. The design helps motors lose less energy. Motors with silicon steel cores use less electricity and make less noise. High magnetic permeability and low core loss help motors control magnetic flux. Motors vibrate less and run quieter, which is good for cars and home electronics. Laminated silicon steel cores also cut down on magnetostriction. This means motors shake less and last longer.

Here are ways Iron Silicon Cores help motors:

Cut down eddy current and hysteresis losses to save energy.

Give good efficiency at low loads, but losses can go up at high loads.

Amorphous metals have even lower core losses and longer life, but cost more.

Relays and solenoids need strong and fast magnetic fields. Iron Silicon Cores focus and boost the magnetic field. This lets relays work with smaller currents. Relays respond quickly because the cores have high magnetic permeability. Silicon steel sheets lower hysteresis and eddy current losses. This saves energy. The cores keep the electromagnetic field steady, so relays work well even when the load changes. Good iron cores last longer and handle tough conditions.

Make strong magnetic fields for relays to work well.

Improve work efficiency and response speed, especially at high frequencies.

Lower energy loss and keep electromagnetic stability.

Help relays last longer and work better.

Iron Silicon Cores help relays and solenoids stay reliable. Silicon in the core raises electrical resistivity and lowers hysteresis loss. This keeps magnetic properties steady over time. For example, Silicon Core Iron B has high permeability and low hysteresis loss. This makes these devices work better and last longer.

Iron Silicon Cores are in many other devices, like armatures, pole pieces, and injector parts. These cores work well in both AC and DC devices. They resist corrosion, so they are good for harsh places. Devices with these cores last longer because the material does not rust easily. Surface treatments and hydrophobic coatings make the cores even stronger. You can use them in places with moisture, chemicals, or very hot or cold temperatures.

|

Device Type |

Benefit of Iron Silicon Cores |

|---|---|

|

Armatures |

Stable magnetic performance, long lifespan |

|

Pole Pieces |

Strong magnetic field, low energy loss |

|

Injector Parts |

Corrosion resistance, reliable operation |

Note: Iron Silicon Cores help electrical devices work well and last longer, even in tough places.

Iron Silicon Cores are used in lots of new devices. Their special features help devices work better and save energy.

|

Material Type |

Efficiency (%) |

|---|---|

|

Silicon-Iron (Si-Fe) |

33–43 |

|

Pure Silicon (Si) |

10–14 |

|

Cu9S5 Nanoparticles |

25.7 |

High magnetic induction helps move energy well.

Low iron loss means less power is wasted.

Strong cores make devices smaller and last longer.

Picking the best core material keeps devices cool. It also helps them last longer and cost less to fix. New ideas use advanced composites and digital modeling. Additive manufacturing is also a new trend. In the future, cores will get even smarter and work better.

Silicon makes the core block electricity better. This means less heat is made. Devices stay cooler and work better. Silicon also makes the core tougher. It helps the core last longer.

Yes, you can use these cores in AC and DC devices. They work in transformers, motors, and relays. High resistivity and low core loss help many machines.

Transformers use these cores to guide magnetic fields well. This means less energy is wasted. Transformers stay cool and work for a long time.

Iron Silicon Cores lower core loss and eddy currents. Less energy turns into heat. Devices use less electricity and last longer.

Yes, these cores resist rust better than plain iron. Silicon helps stop rust and corrosion. You can use them where there is moisture or chemicals.

By continuing to use the site you agree to our privacy policy Terms and Conditions.