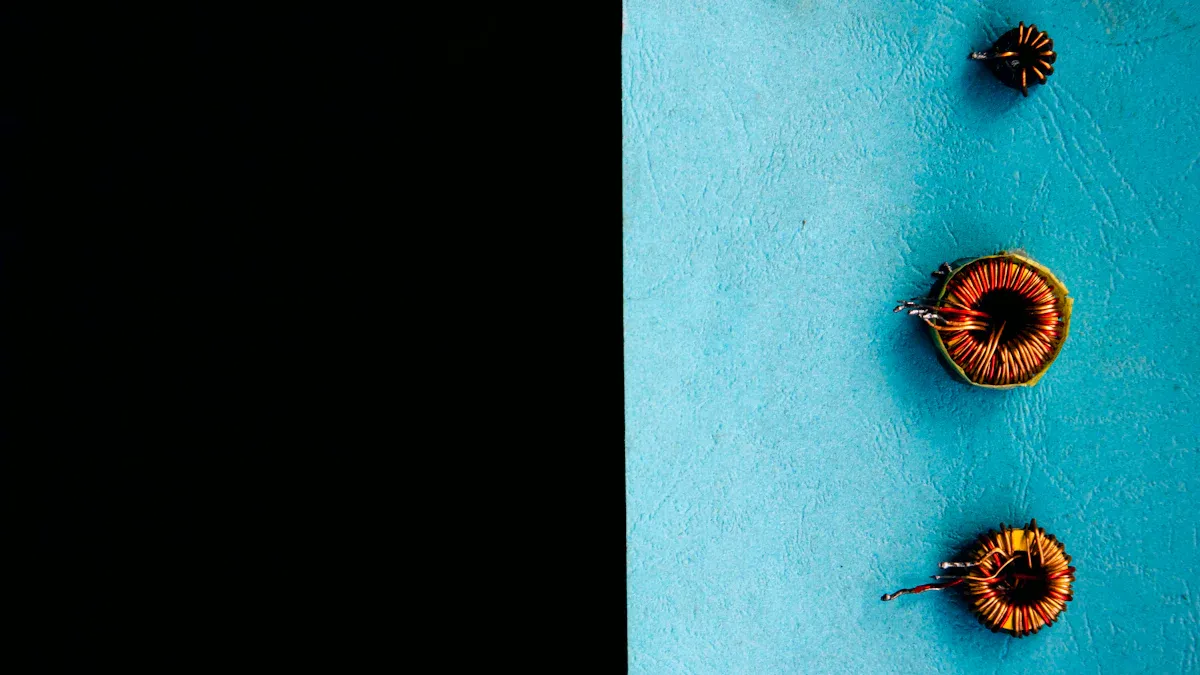

You use electronic devices that should stay cool and work longer. A high flux ferrite core helps with this by handling more magnetic flux. It also supports higher currents. Many engineers pick these cores because they make things work better. Some designs lose up to 70% less energy than regular ferrite cores. You also avoid problems like getting too hot or breaking down. These cores keep transformers and inductors steady, even when it gets hot. This helps your parts stay safe and work well.

High flux ferrite cores can hold more magnetic flux. This lets devices be smaller. Devices also work better.

These cores help stop energy loss. They keep devices cooler. Devices last longer because of this.

High flux ferrite cores work well at high temperatures. This makes them good for many uses.

Picking the right core helps devices work better. This is important for power supplies and inductors.

Think about what your circuit needs. This helps you pick the best core. Your device will work its best.

You want your devices to use more power but not get bigger. A high flux ferrite core lets this happen. It can handle higher AC voltage and DC bias current. The core does not reach saturation as fast. This means you can send more current through inductors and transformers. You do not have to worry about the core losing its magnetic power.

You need less wire to get the same inductance.

Inductors and transformers are smaller and lighter.

You save space and make your designs weigh less.

Tip: High flux ferrite cores help you make small devices that still work well.

High flux ferrite cores waste less energy. They do not turn as much energy into heat, even at high frequencies. This makes power supplies and converters work better. Your parts also last longer because they stay cooler.

|

Core Type |

Permeability Range |

Core Loss Characteristics |

|---|---|---|

|

High Flux Ferrite |

N/A |

Lower core loss at high frequencies than standard ferrite and powdered iron. |

|

Standard Ferrite |

125 to 5,000 |

Higher core loss, especially at RF frequencies. |

|

Powdered Iron |

4 to 35 |

Lower core loss, more energy needed to saturate. |

Ferrite materials help lower core losses, so parts are smaller and lighter.

At high frequencies, you use less wire, which helps make things smaller.

Ferrite cores keep things efficient, so your design stays small and works well.

TDK’s power ferrite materials can cut core loss in main transformers by up to 40% compared to old materials.

You want your devices to work well, even when hot. High flux ferrite cores keep their magnetic power over a wide temperature range. This makes them good for many uses in factories and businesses.

High flux cores stay steady from room temperature up to 125 °C.

With special binders, you can use them up to 200 °C.

Inductors and transformers keep working, even in tough places.

Note: High flux ferrite cores help stop overheating and breakdowns, so your electronics last longer.

You might wonder how these two cores are different. The biggest differences are in how much magnetic flux they can handle, how much space you save, and how well your device works.

|

Feature |

Standard Ferrite Core |

High Flux Ferrite Core |

|---|---|---|

|

Saturation Flux Density |

Lower |

Higher |

|

Size for Same Inductance |

Larger |

Smaller |

|

Efficiency |

Moderate |

Higher |

|

Thermal Stability |

Good |

Excellent |

A high flux ferrite core can take more magnetic flux before it saturates. This lets you send more current through inductors or transformers without losing power. You also get a part that is smaller and lighter. This helps when you need to fit things into small spaces.

Tip: If you build telecom or car electronics, you need steady and small parts. High flux ferrite cores give you both.

Here are some reasons to pick a high flux ferrite core instead of a standard one:

You need to handle more magnetic flux before saturation.

You want your device to stay steady, even if power changes fast.

You need a small design for tight spaces.

|

Application Type |

Reason for Preference |

|---|---|

|

Telecom Systems |

High current changes a lot, so you need steady and small parts. |

|

Automotive Electronics |

Needs to handle power surges and still work well in small spaces. |

In real life, like in motor controllers or power supplies, a high flux ferrite core keeps things steady. It handles quick power changes and helps stop problems like distortion or losing inductance.

You might also compare high flux ferrite cores to powdered iron cores. Both have good points, but they act differently with high current and DC bias.

|

Core Type |

DC Bias Current Handling Capability |

Saturation Characteristics |

|---|---|---|

|

High Flux Ferrite |

Medium losses, saturates quickly |

Inductance drops fast |

|

Powdered Iron |

Handles more current before saturating |

Inductance drops slowly |

A high flux ferrite core has high permeability and works well. But it can saturate fast if you use too much current. When this happens, inductance drops quickly. Powdered iron cores can take more DC bias current. They do not saturate as fast, and their inductance drops slowly.

|

Characteristic |

High Flux Ferrite Cores |

Powdered Iron Cores |

|---|---|---|

|

Relative Permeability |

Higher |

Lower |

|

Saturation Magnetic Flux |

About 5000Gs |

Over 10000Gs |

|

Saturation Characteristics |

Drops sharply |

Drops slowly |

|

Inductance Behavior |

Drops fast when saturated |

Drops slowly when saturated |

|

DC Bias Characteristics |

Not as good |

Better |

High flux ferrite cores are best for low losses at high frequencies.

Powdered iron cores are better for circuits with high DC bias current.

Note: For high DC bias, you may want Kool Mμ or powdered iron cores. For high-frequency, low-loss needs, high flux ferrite cores are often better.

You should always pick the right core for your circuit. If you want high efficiency and a small size, high flux ferrite cores are a good choice. If your circuit needs to handle high DC bias, powdered iron cores may be better.

High flux ferrite cores are used in switching power supplies. These cores help circuits work well at high frequencies. They keep things efficient and save energy. You can change AC power to DC power with little waste. High flux ferrite cores also help stop electromagnetic interference (EMI). This keeps your devices working without problems.

These cores have low core loss, so they are efficient.

Transformers can be smaller and lighter, which saves space.

You can use high currents without the core getting too hot.

Tip: Pick high flux ferrite cores if you want your power supply to stay cool and last longer.

Here is a table that shows where high flux ferrite cores work best and what they do:

|

Application |

Performance Benefits |

|---|---|

|

Switching Power Supplies |

High efficiency and works at high frequencies, good for changing AC to DC power. |

|

Radio Frequency (RF) Transformers |

Works well at high frequencies for matching signals and changing frequencies. |

Inductors and chokes help filter noise and keep current steady. High flux ferrite cores make these parts work better. They can store more energy to block unwanted signals. This helps keep voltage smooth and circuits stable, even if current changes fast.

High flux ferrite cores help lower noise in filters and high-current circuits.

You get less core loss, so inductors and chokes stay cool.

These cores stop saturation, so parts work well with large AC voltages.

|

Property |

Observation |

|---|---|

|

Frequency Response |

Lower permeability helps at higher frequencies. |

|

Core Material Losses |

Harder core materials can cause more losses and less efficiency. |

|

Eddy Currents |

Conductive cores can make eddy currents, which heat things up. |

Note: If you need to cut noise and keep circuits working well, high flux ferrite cores are a good choice. You get smaller, better filters and strong performance in tough jobs.

You want your electronics to work well and not get hot. Choosing the right high flux ferrite core helps you do this. First, look at what your circuit needs. Check the frequency, the highest current, and the voltage. High flux ferrite cores are best for circuits that need to be efficient at medium or high frequencies.

Figure out the highest current so the core does not saturate.

Pick a core with high magnetic permeability and flux density for good results.

Choose a shape and size that fits your design and can handle your current.

Make sure the core works well at all the temperatures your device will see.

Look at the material and price to fit your budget and needs.

Check if the core meets rules for safety and the environment.

Tip: If your device needs to handle lots of current, stay efficient, and work in hot places, a high flux ferrite core is a good pick.

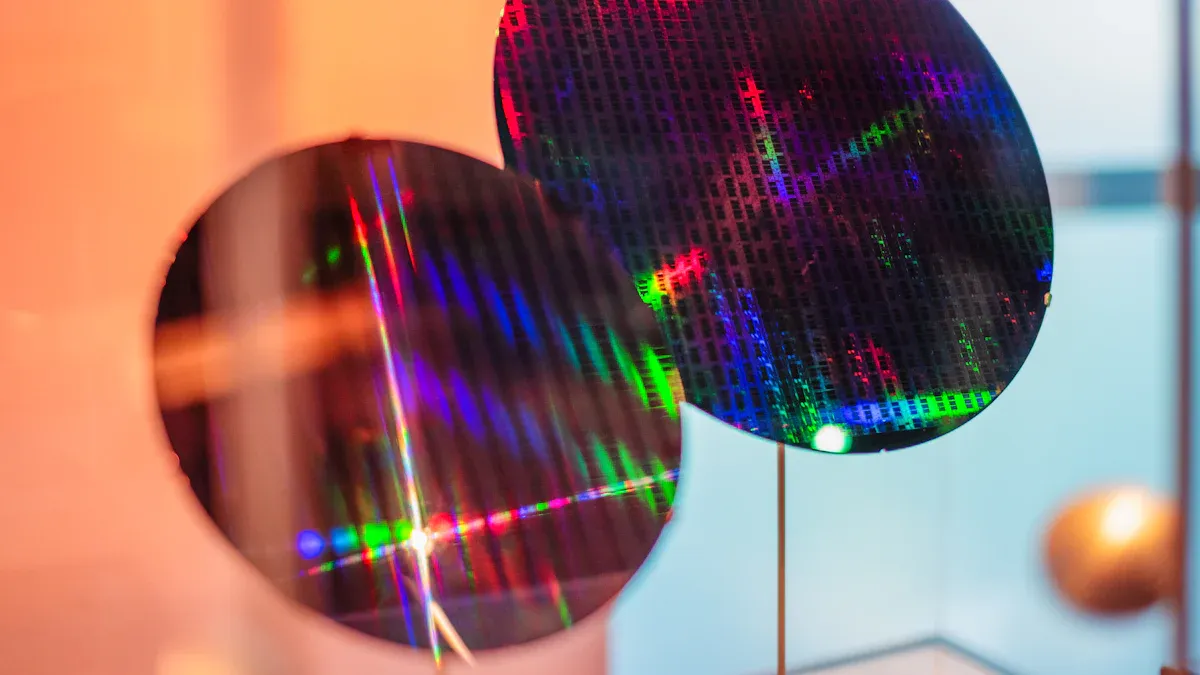

Manufacturers mix powders, mold them, and heat them to keep quality high. They check each core to make sure it meets size and magnetic rules. Coating and insulation help stop short circuits and keep your device safe.

High flux ferrite cores have many good points, but they also have limits. These cores have lower permeability than iron, so you might need more wire turns to get the same inductance. At low frequencies, the core can saturate fast, so it may not work well for 50/60 Hz power lines.

Using ferrite cores at low frequencies can make the core bigger and cause more wire loss.

High flux ferrite cores can cost more than amorphous or powdered iron cores, especially for big projects.

Being sensitive to temperature can change how well they work in very hot or cold places.

Some jobs, like those needing very quiet parts or steady inductance when loads change, might work better with other cores like gapped ferrite, powder cores, or KoolMμ.

|

Core Material |

Best Use Case |

Main Drawback |

|---|---|---|

|

High Flux Ferrite |

High-frequency, efficient designs |

Sensitive to temperature, cost |

|

Powder Cores |

High DC bias, stable inductance |

Lower permeability |

|

Amorphous |

Cost-effective, low losses |

May not suit all frequencies |

Note: Always pick the core that fits your circuit’s needs. Think about cost, how well it works, and safety rules before you choose.

You get lots of good things when you pick a high flux ferrite core. These cores help you make devices that are smaller and stay cool. Your devices also work better and last longer. Look at the table below for a quick look:

|

Advantage |

Description |

|---|---|

|

High Energy Storage |

Holds more energy in a small space |

|

Temperature Stability |

Works well when it is hot or cold |

|

Low Power Consumption |

Needs less energy and makes less heat |

|

Broad Application Range |

Good for power supplies, filters, and more |

You can also fix problems like too much heat, noise, and big size. New materials and better ways to make these cores help them work even better. Try using them in your next power electronics project to get better results.

A high flux ferrite core is a special magnetic material. It is used in transformers and inductors. This core can store more energy than regular ferrite cores. It also lets more current pass through.

You get better efficiency and a smaller part. High flux ferrite cores let more current flow before they saturate. Your devices stay cooler and last longer.

Tip: Pick high flux ferrite cores for power supplies and circuits that need to work well.

It is not good to use them at low frequencies. These cores can saturate fast and lose efficiency. For 50/60 Hz power lines, pick a different core material.

High flux ferrite cores waste less energy. Your devices stay cooler because less energy turns into heat. This helps your electronics last longer and work better.

High flux ferrite cores can cost more than standard ferrite or powdered iron cores. The higher price gives you better performance, smaller size, and longer life for your devices.

By continuing to use the site you agree to our privacy policy Terms and Conditions.