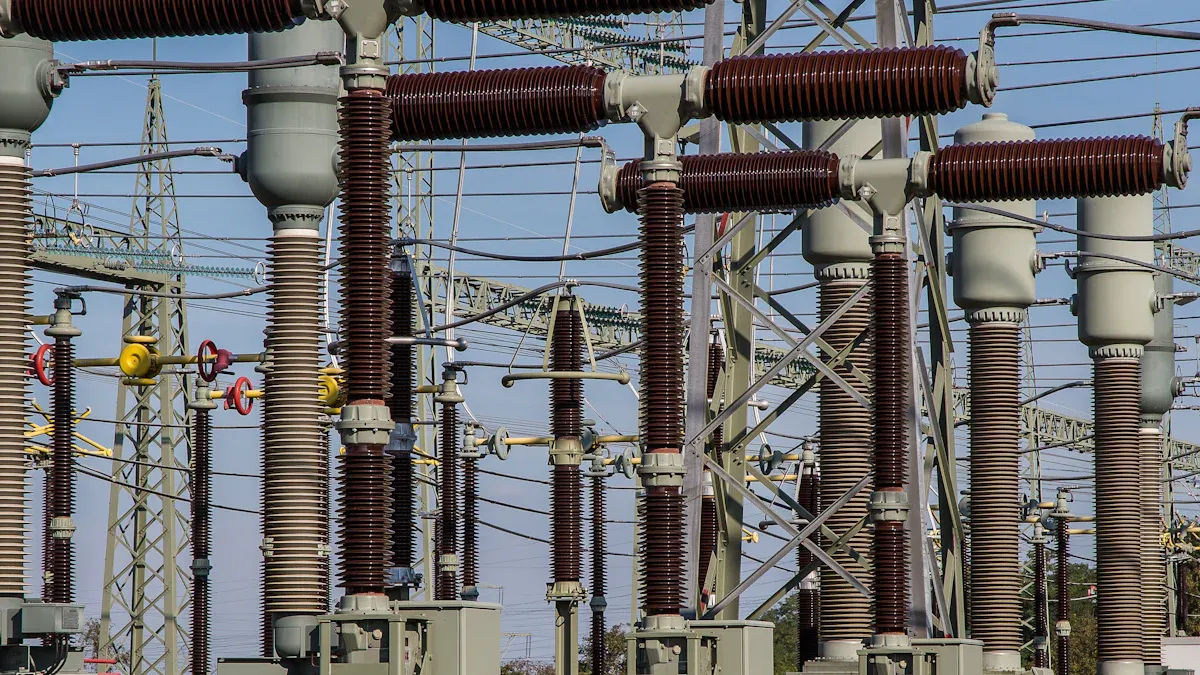

A city’s power grid uses switchgear to protect people and buildings. Switchgear helps control and guard electrical circuits in big power systems. Magnetic materials help switchgear work by moving electricity and helping switches open or close. Engineers and electricians need to know how magnetic materials change safety and how well things work.

Magnetic materials are very important for switchgear. They help control and protect electrical circuits in power systems.

There are different magnetic materials, like silicon steel and amorphous cores. Each type has special features that make switchgear work better and safer.

Newer materials, like nanocrystalline cores, help devices in switchgear measure more accurately. They also make the devices work more reliably.

Magnetic materials help save energy by making transformers lose less energy. This helps power systems use less energy.

Recycling and using magnetic materials in good ways help green energy solutions. This makes power systems safer and better for the environment.

Switchgear uses different magnetic materials to help control power. Each type has its own special features. Some work better in certain switchgear parts.

|

Type of Magnetic Material |

Basic Characteristics |

Typical Applications in Switchgear |

|---|---|---|

|

Silicon Steel Core |

Low loss, stable magnetic properties |

Current transformers, voltage transformers, small transformers, reactors |

|

Amorphous Core |

Very low iron loss, high magnetic permeability |

High-precision current transformers, sensors |

|

Nanocrystalline Core |

Higher permeability than amorphous, wide frequency response |

Zero-sequence current transformers, differential protection devices |

|

Permanent Magnet |

Strong, stable magnetism |

Vacuum circuit breaker actuators |

|

Magnetic Powder Core |

Good stability, reduces electromagnetic interference |

Auxiliary power supplies, filter inductors |

Note: Permanent magnet materials are used in about 36.47% of switchgear. Soft magnetic materials like silicon steel are growing by 9.48% in the market.

Magnetic materials are important in many switchgear parts. They help the equipment work safely and well.

Current Transformers (CTs) and Voltage Transformers (VTs):

The core moves the magnetic field from one winding to another.

The core can handle strong magnetic flux without getting full.

Low core losses help keep things cool and save energy.

Stable core materials make sure things work well, even if it gets hot or cold.

New materials like amorphous alloys help save more energy.

Current transformers help measure current safely. Voltage transformers help measure voltage safely.

Actuators and Sensors:

Permanent magnets help actuators hold the switch in place. This helps the switch last longer and use less energy.

Magnetic powder cores help keep power supplies steady. They also block unwanted signals to protect control circuits.

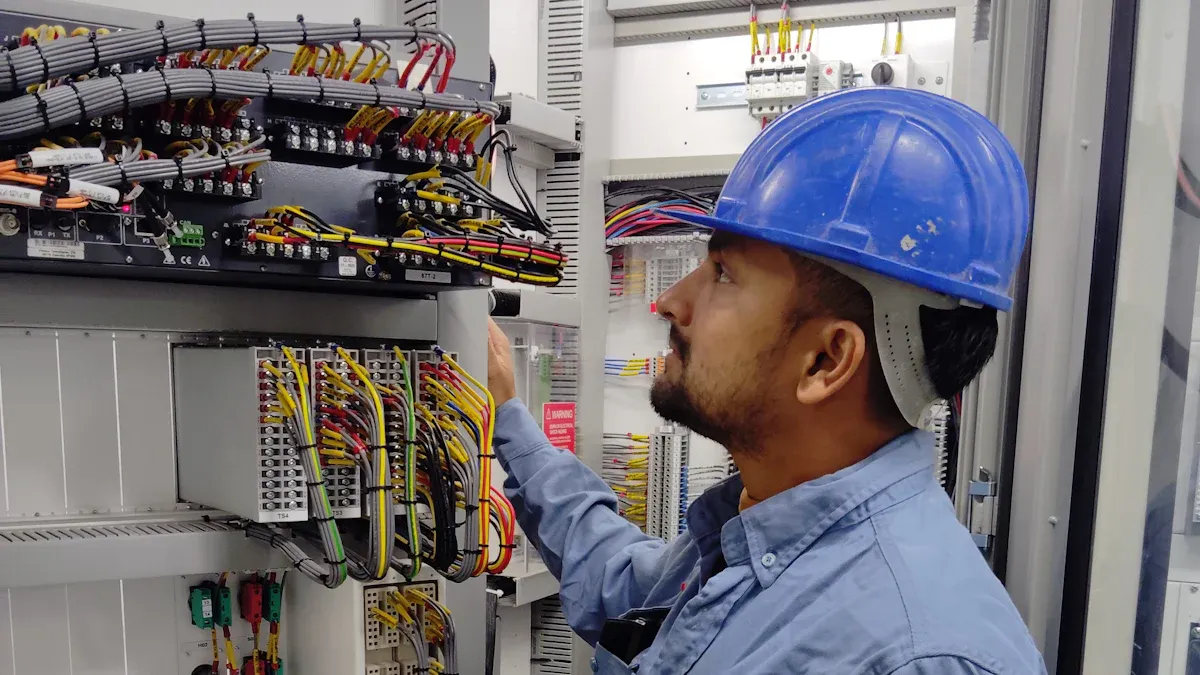

Designers pick magnetic materials based on what each part needs. Silicon steel is good for transformer cores because it keeps losses low. Amorphous and nanocrystalline cores help sensors and protection devices work fast and right. Permanent magnets help actuators work better and last longer.

Switchgear needs to measure and protect fast to keep things safe. Magnetic materials help transformers and sensors measure current and voltage well. Silicon steel cores, amorphous cores, and nanocrystalline cores are used for this. Engineers pick these materials to make transformers work better.

|

Application |

Description |

|---|---|

|

Quality Control |

Makes sure measurements are right for magnetic products. |

|

Shielding Tests |

Checks if electronics are safe from magnetic fields. |

|

Residual Particle Inspection |

Looks for leftover magnetic bits after making parts. |

|

Magnetic Field Assessment |

Checks how strong and shaped the magnetic field is. |

|

Magnetic Field Leakage |

Looks for leaks to follow shipping rules. |

|

Magnetic Field Confirmation |

Makes sure the magnetic field matches the current. |

Magnetic shielding devices use soft magnetic materials like permalloy. These guide magnetic flux and help measurements be more accurate. Active compensation coils make a field to block outside effects. Degaussing coils work with shields to lower stress from putting things together. This keeps measurements steady.

Studies show new magnetic materials can change their magnetic domains when switching current. This helps sensors and transformers react fast and right to problems.

Modern switchgear uses permanent magnets and magnetic powder cores. These make actuators and power supplies work better. Vacuum interrupters with magnetic actuation need less fixing than old ones. They have fewer moving parts, so they last longer.

Vacuum interrupters cut arcing time and wear on contacts.

Magnetic actuation makes things more reliable by being simple.

Permanent magnets help switches stay in place without extra power.

Saving energy is important for all power systems. Silicon steel cores and amorphous cores lower losses in transformers and reactors. This keeps things cool and saves energy. Magnetic powder cores help block bad signals and keep power steady. This cuts down on wasted energy.

Magnetic materials also make things safer. Devices like magnetic contactors and vacuum interrupters protect motors and circuits from faults. Magnetic coils in these devices stop fault currents fast. This keeps people and equipment safe.

In the last few years, engineers made big changes in magnetic materials for switchgear. They now use nanocrystalline and amorphous cores to make things work better and waste less energy. These materials react fast and use less power because they have high initial permeability and low coercivity. New alloys like FeSiB, FeMB, and FeMC give transformers and inductors better magnetic properties.

|

Advancement |

Description |

|---|---|

|

Nanocrystalline Materials |

High permeability, low coercivity, better than ordinary crystalline types |

|

Alloy Series |

FeSiB, FeMB, FeMC alloys for improved magnetic performance |

|

Applications |

Used in high-frequency electronics, transformers, and inductors |

Amorphous and nanocrystalline materials help switchgear work well in high-frequency power supplies for computers and communication systems. As more people use electronics, the need for these materials keeps growing.

Smart grids and digital systems need advanced sensors and magnetic materials. TMR sensors use special magnetic effects to sense things with high accuracy and low power. These sensors help smart grids find electrical data very well. Soft magnetic materials like silicon steel and nanocrystalline cores help sensors in switchgear work better and more accurately.

TMR sensors measure current very exactly.

Sensors with non-saturable magnetic cores are small and very accurate.

Microcontroller-based protection relays use these sensors instead of old transformers, making switchgear safer and more reliable.

Permanent magnets and magnetic powder cores also help actuators and power supplies work better and stay steady.

Smart switchgear uses new magnetic materials to help with digital monitoring and remote control. This makes power systems smarter.

Magnetic materials help green energy and protect the environment. Wind turbines and solar panels use these materials to turn wind and sunlight into electricity. Permanent magnets made from rare earth elements are very important for electric motors in renewable energy systems. In five years, wind turbines around the world may reach 680 GW, so more good magnetic materials are needed.

|

Sustainability Challenge |

Solution |

|---|---|

|

High recycling costs |

Hydrogen-assisted recycling, custom magnet design |

|

Difficult collection and transport |

Improved logistics and recycling channels |

|

Energy-intensive recycling |

Use renewable energy in recycling |

|

Secondary waste generation |

Green solvent technologies |

Now, companies recycle metals from old products and use more recycled materials. These actions help cut down on waste and keep the planet cleaner.

Magnetic materials such as silicon steel, amorphous cores, nanocrystalline cores, permanent magnets, and magnetic powder cores are very important in switchgear. These materials help switchgear work safely and well. They power sensors, relays, and arc-flash protection systems. Good magnetic materials help electric motors work better. They also help systems get ready for the future. The global market for magnetic materials is growing quickly. This means new ideas will keep making power systems safer and smarter.

Silicon steel core helps transformers and reactors work well. It cuts down on energy loss and keeps magnetic properties steady. Engineers use it in current transformers and voltage transformers.

Amorphous cores have very low iron loss. They help sensors and transformers react fast. These cores make switchgear safer and save energy.

Nanocrystalline cores have high permeability and work in many frequencies. They help zero-sequence current transformers find faults quickly. This keeps electrical systems safe.

Permanent magnets keep switches in place in vacuum circuit breakers. They lower wear on parts and help switchgear last longer.

Magnetic powder cores keep auxiliary power supplies steady and block bad signals.

These cores protect control circuits and make switchgear safer.

By continuing to use the site you agree to our privacy policy Terms and Conditions.